Leon Mk1

|

|

|

|

|

|

|

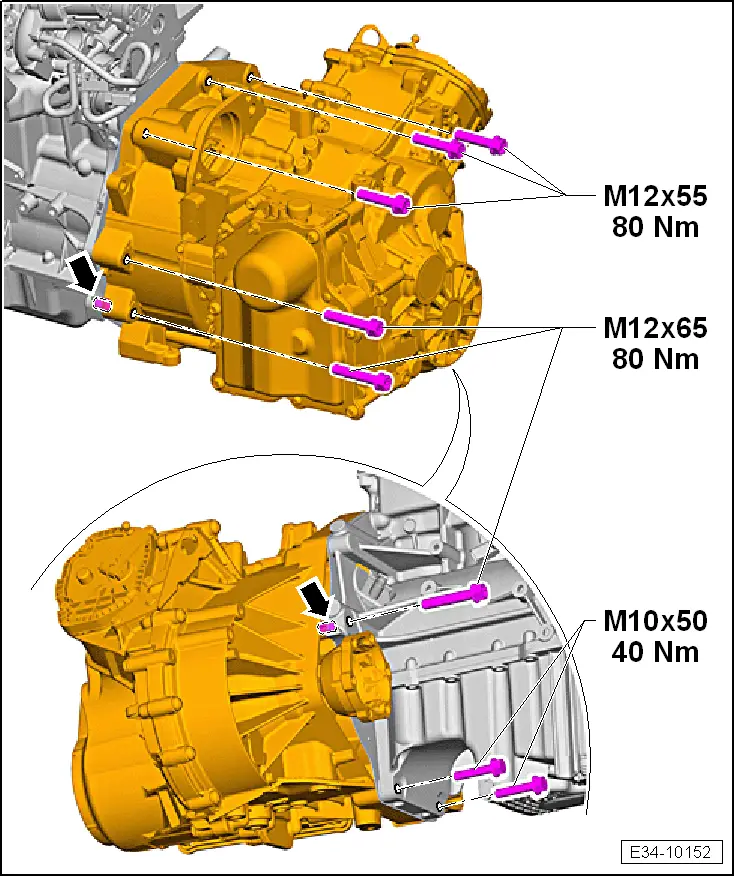

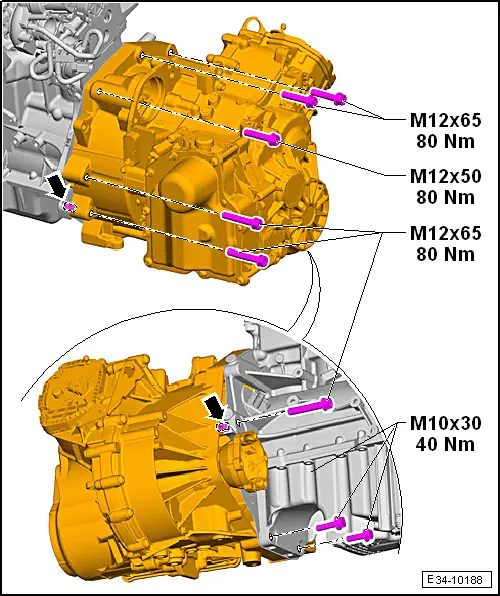

| M12 - | 80 Nm |

| M10 - | 40 Nm |

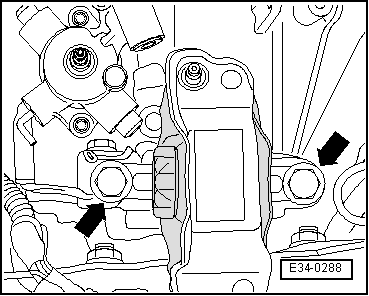

| - | The arrows show the dowel sleeves. |

|

| M12 - | 80 Nm |

| M10 - | 40 Nm |

| - | The arrows show the dowel sleeves. |

|

| M12 - | 80 Nm |

| M10 - | 40 Nm |

| - | The arrows show the dowel sleeves. |