Leon Mk1

|

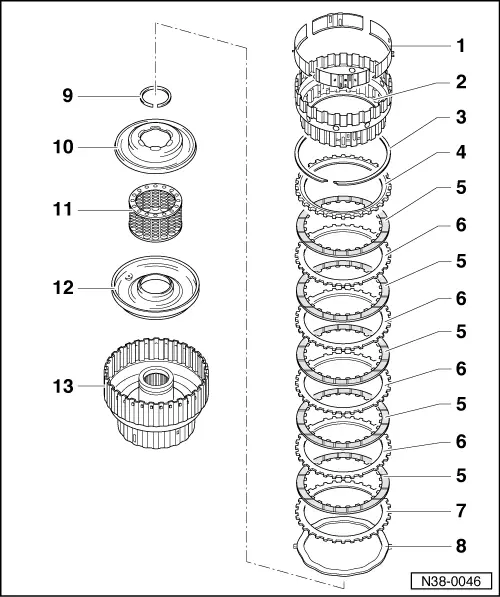

Dismantling and assembling 1st to 3rd gear clutch -K1-

Dismantling and assembling 1st to 3rd gear clutch -K1-

|

|

|

|

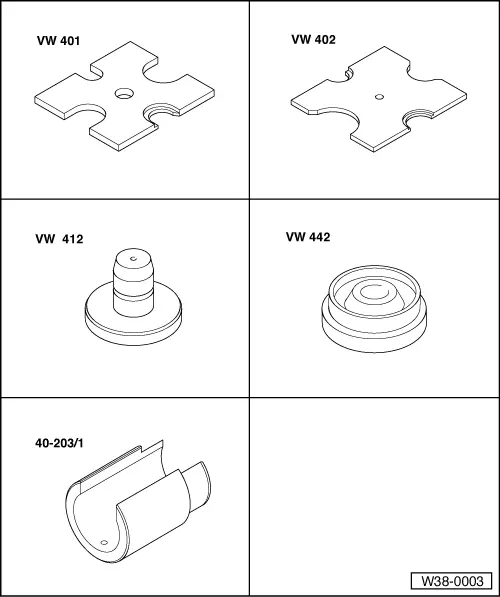

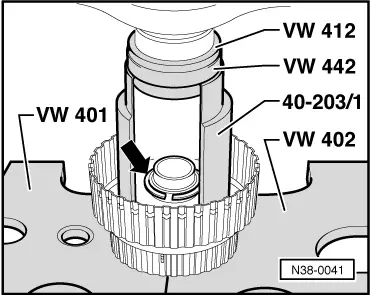

Special tools and workshop equipment required

|

|

|

|

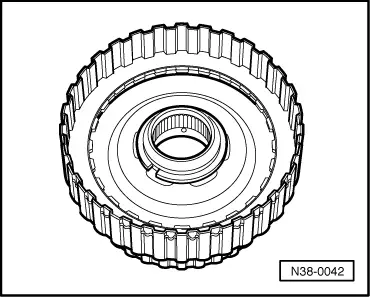

Only when cleaning or carrying out visual check the clutch must be dismantled. On some gearboxes the clutches -K1- and -K3- may be pressed together. Pressing -K1- off -K3- Pressing -K1- onto -K3- => Page 37-84 |

|

|

|

|

|

|

|

|

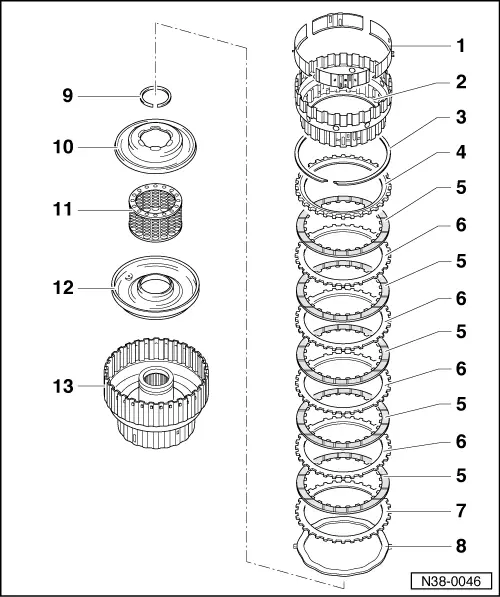

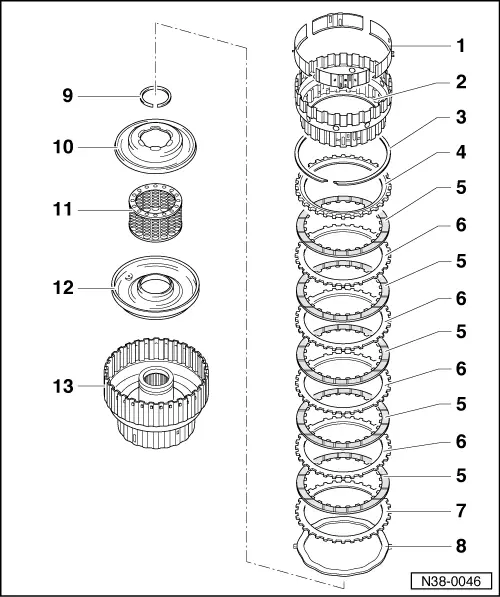

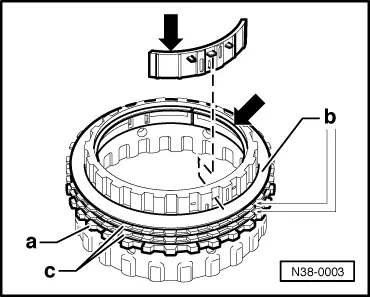

→ Fig.1 Removing and installing circlip

|

|

|

|

→ Fig.2 Fitting thrust plate and plates onto inner plate carrier

|

|

|

|

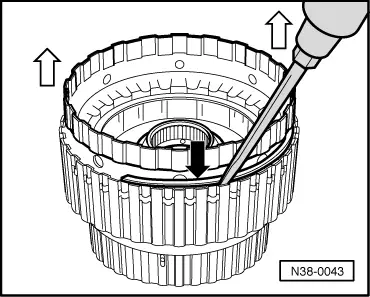

→ Fig.4 Inserting inner plate carrier and installing circlip (arrow).

|