Leon Mk1

|

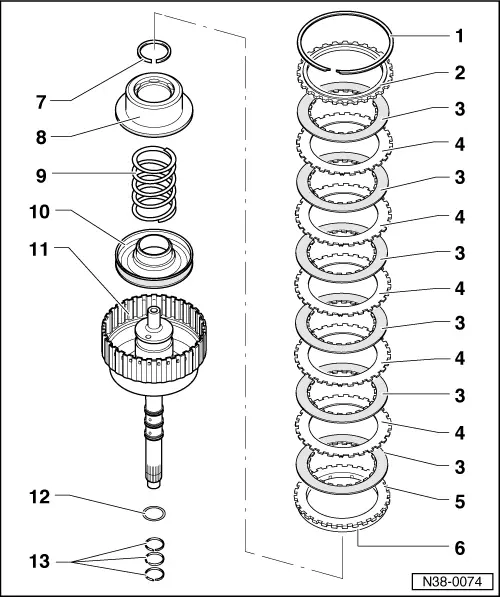

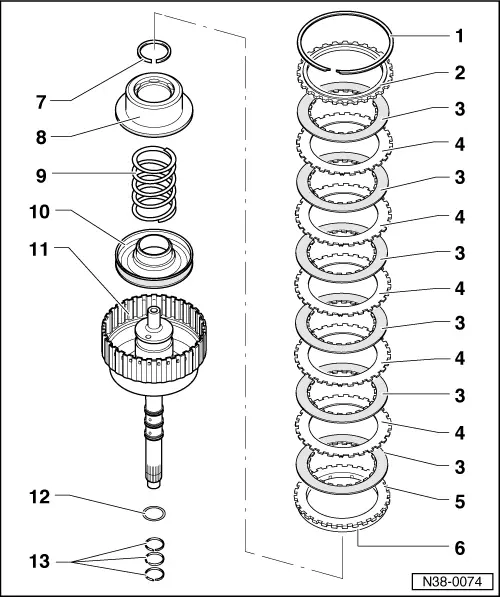

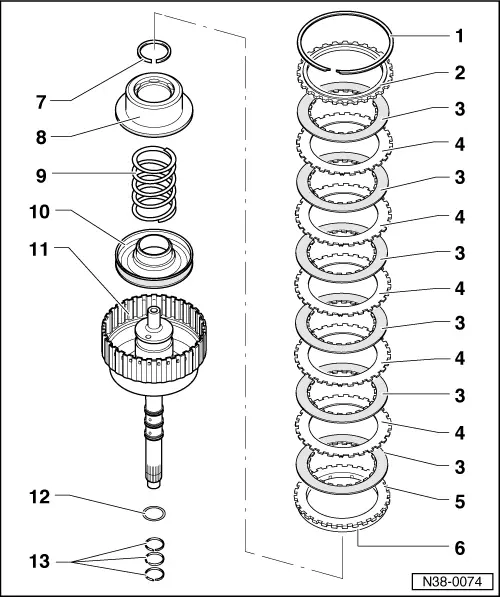

Dismantling and assembling 3rd and 4th gear clutch -K3- with turbine shaft

Dismantling and assembling 3rd and 4th gear clutch -K3- with turbine shaft

|

|

|

|

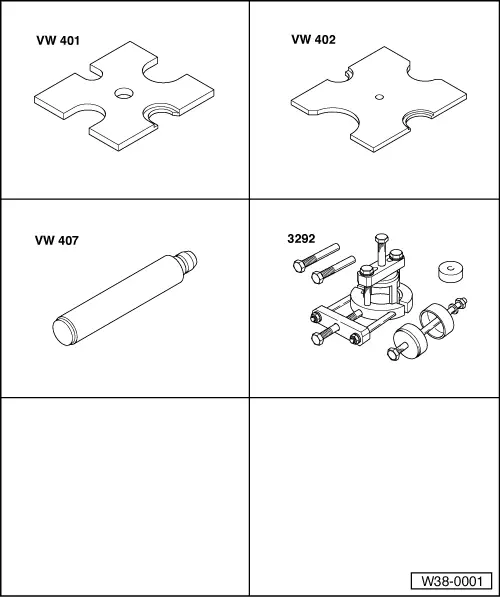

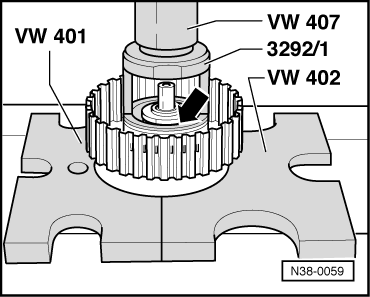

Special tools and workshop equipment required

|

|

|

|

Only when cleaning or carrying out visual check the clutch must be dismantled. On some gearboxes the clutches -K1- and -K3- may be pressed together. Pressing -K1- off -K3- Pressing -K1- onto -K3- => Page 37-84

|

|

|

|

|

|

|

|

|

|

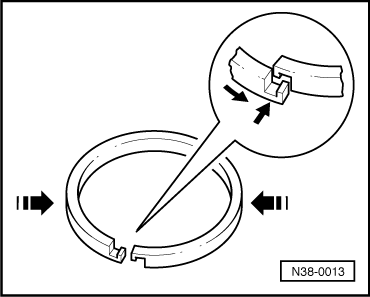

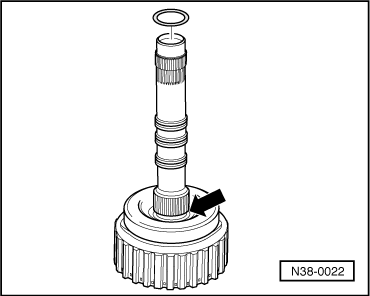

→ Fig.1 Removing and installing circlip (arrow)

|

|

|

|

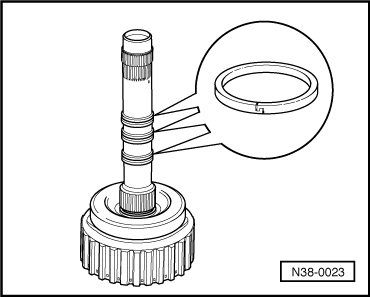

→ Fig.2 Checking seating of piston rings

|

|

|

|

→ Fig.4 Installing O-ring

|