Leon Mk1

|

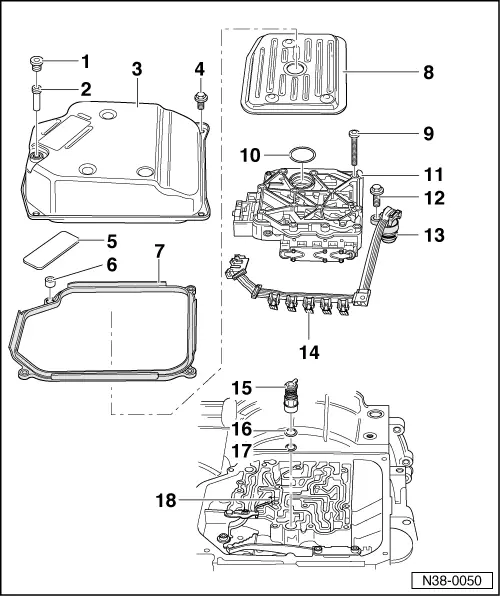

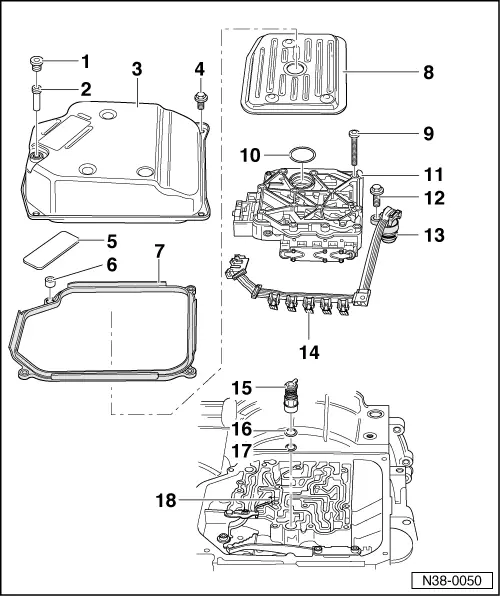

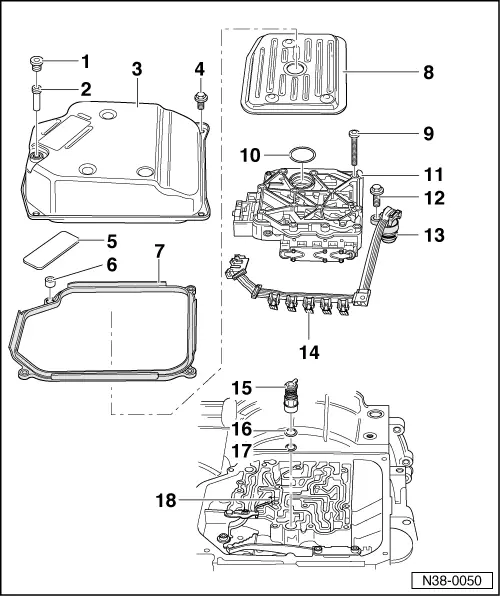

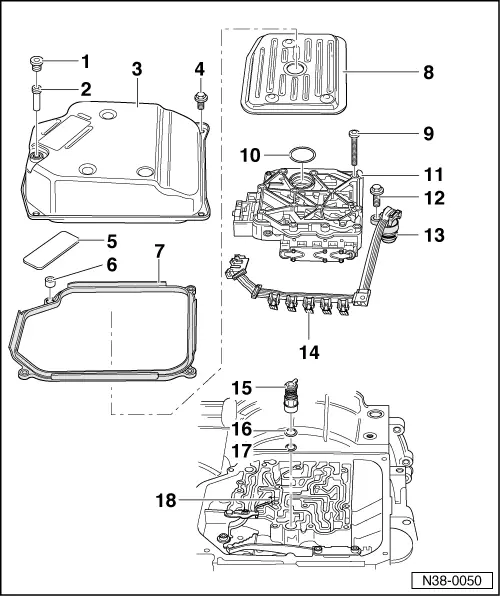

Removing and installing valve chest

Removing and installing valve chest

|

|

|

|

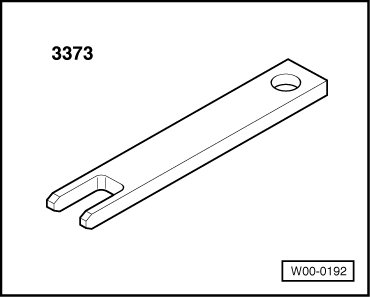

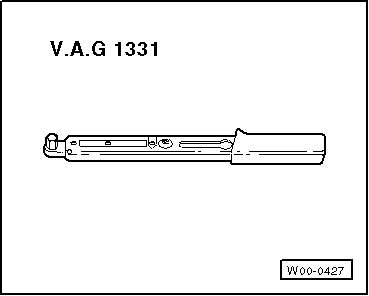

Special tools and workshop equipment required

|

|

|

|

|

|

|

Warning!

Do not run engine or tow vehicle with oil pan removed or when there is no ATF in gearbox.

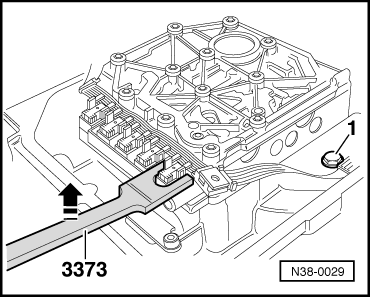

The conductor strip can be removed individually.

|

|

|

|

|

|

|

|

|

|

|

|

|

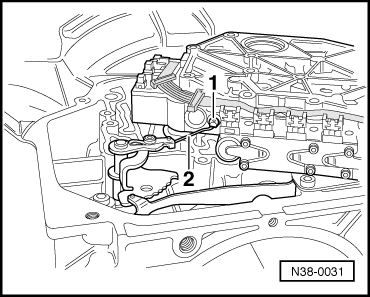

→ Fig.1 Draining ATF

|

|

|

|

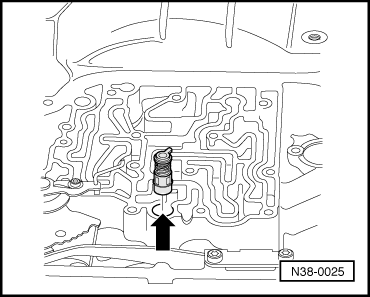

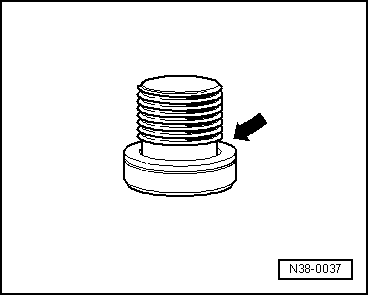

→ Fig.2 Replacing plug seal

|

|

|

|

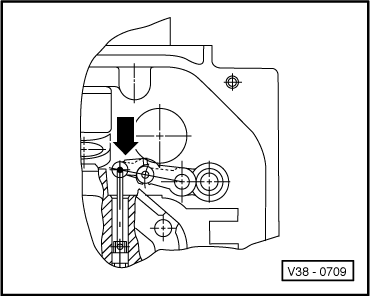

→ Fig.3 Removing conductor strip

|

|

|

|

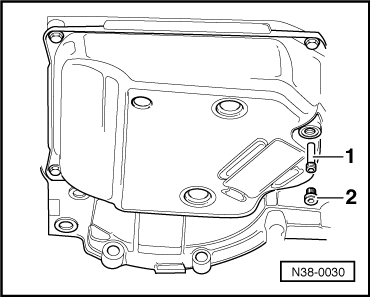

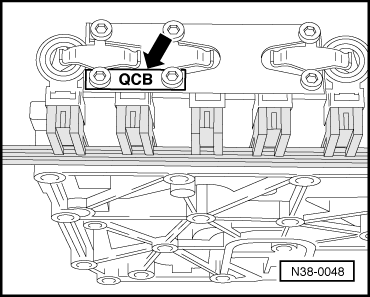

→ Fig.6 Identification of valve chest Code letters are stamped on a metal tab. Metal tab must remain on the valve chest. Allocation valve chest/gearbox =>from Page 00-3 |

|

|

|

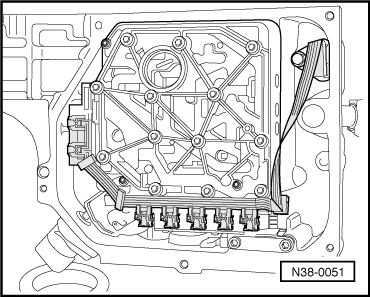

→ Fig.9 Installing valve body

|

|

|

|

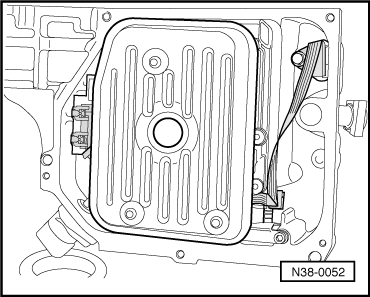

→ Fig.10 Installing ATF screen

|