Leon Mk1

|

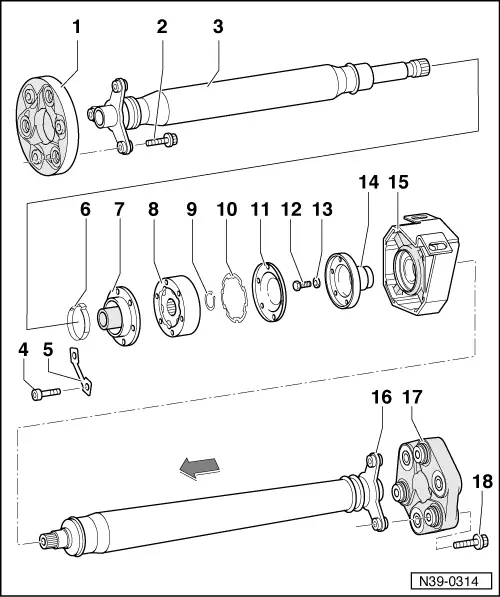

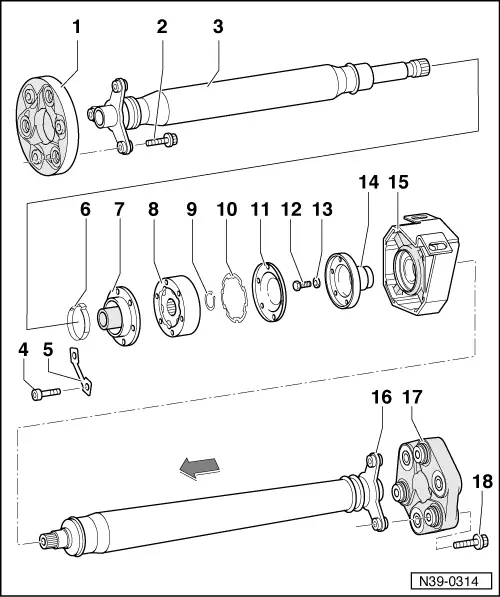

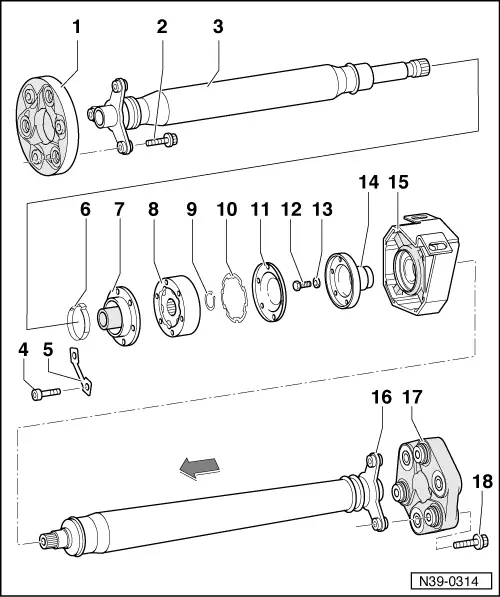

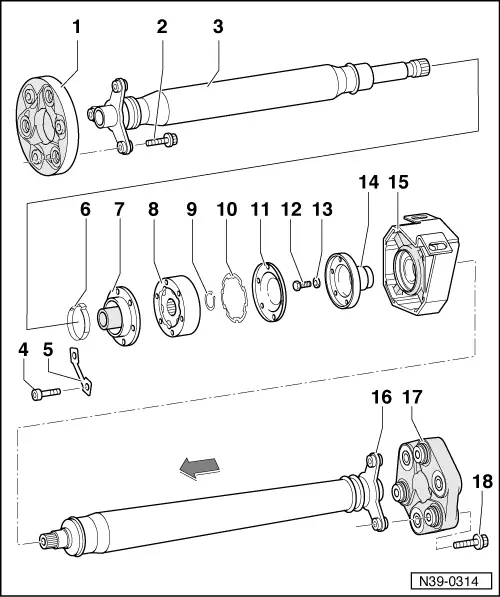

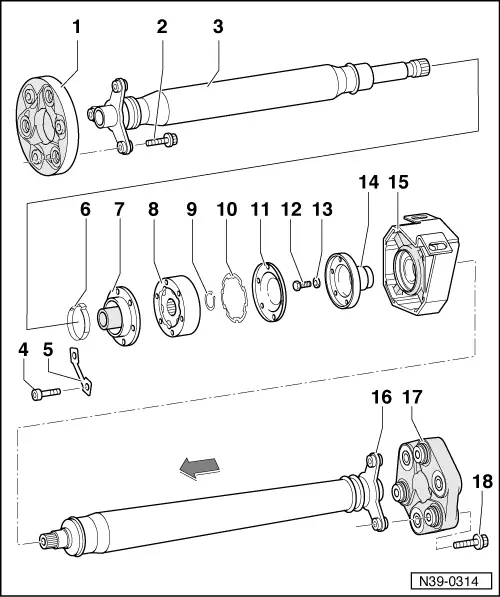

Servicing propshaft

Servicing propshaft

|

|

|

|

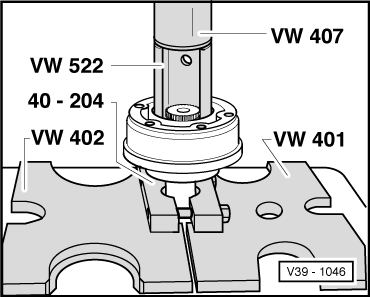

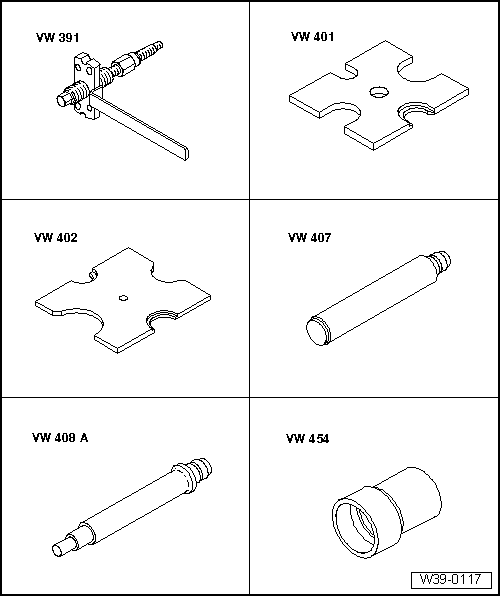

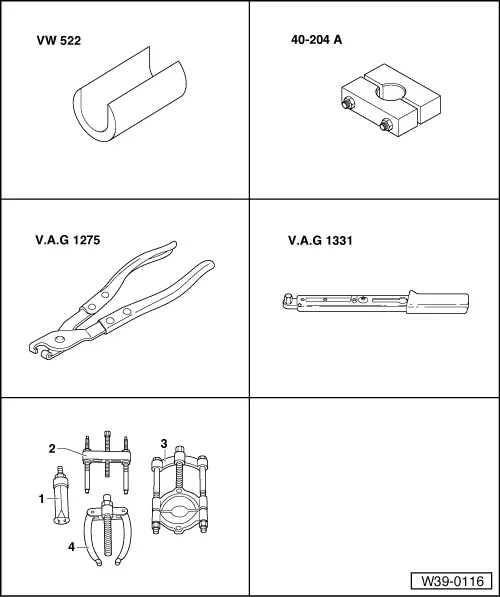

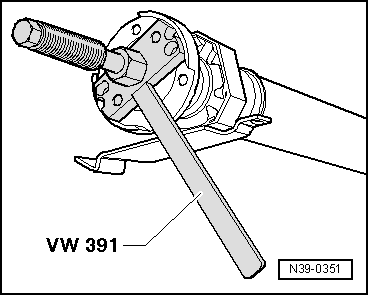

Special tools and workshop equipment required

|

|

|

|

|

|

Arrows point in direction of travel |

|

|

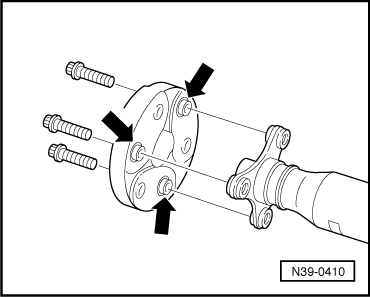

Do not use hexagon bolts. Arrows point in direction of travel |

|

|

Arrows point in direction of travel |

|

|

Arrows point in direction of travel |

|

|

Arrows point in direction of travel |

|

|

Do not use hexagon bolts. Arrows point in direction of travel |

|

|

|

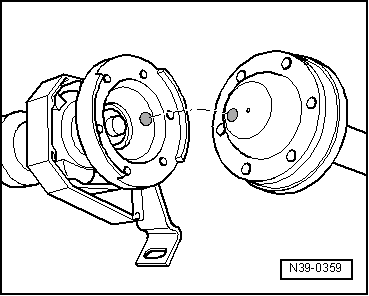

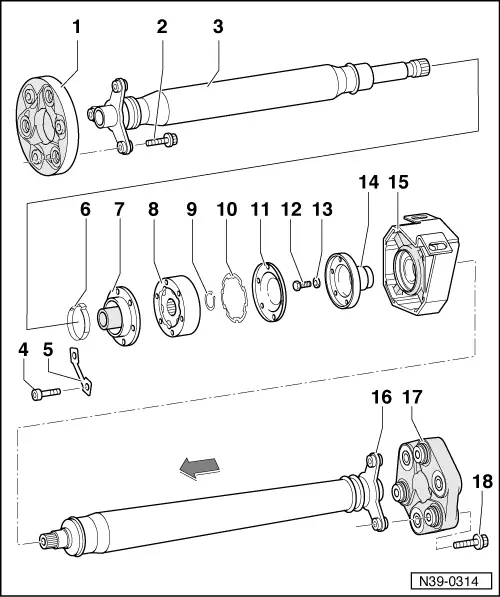

→ Fig.1 Front flexible coupling installation position

|

|

|

|

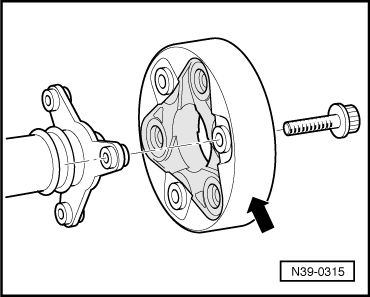

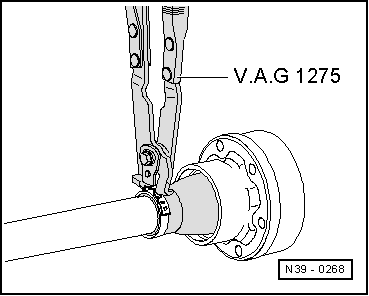

→ Fig.3 Pressing off constant velocity joint |

|

|

|

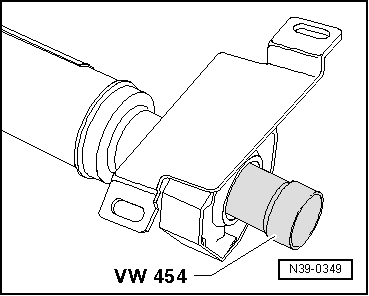

→ Fig.5 Tensioning clamp Allocate clamp in repair cases via parts catalogue. |

|

|||||||||

|

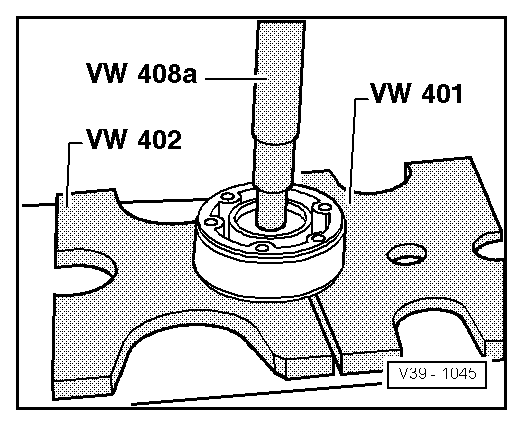

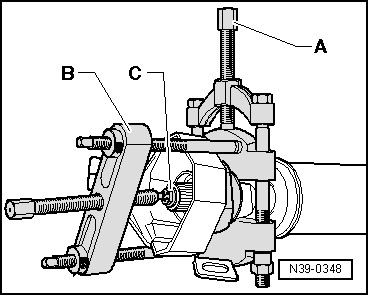

→ Fig.6 Pulling intermediate bearing off

| |||||||||

|

|

|

→ Fig.7 Driving intermediate bearing on

|

|

|

|

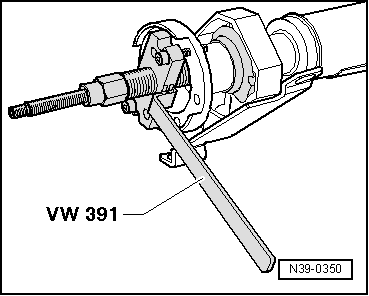

→ Fig.8 Pulling flange off |

|

|

|

→ Fig.9 Pulling flange on |

|

|

|

→ Fig.10 Rear flexible coupling installation position

|