| Gearbox, for vehicles with turbo diesel engine. Install |

| Install in reverse order, observing following: |

Note | t

| Clean ATF pipes and ATF cooler before installing a replacement gearbox → Chapter. |

| t

| Always replace self-locking nuts and bolts during assembly. |

| t

| Renew oil seals, gaskets, O-rings and bolts which are tightened by turning through a specified angle. |

| t

| Clean the teeth of the gearbox drive shaft and the teeth of the dual mass flywheel, remove any corrosion and apply a fine layer of grease. Allocation → Spare parts catalogue. It is essential to remove excess grease. |

| t

| Re-attach all cable ties at the same locations when re-installing. |

| –

| Check whether there are adjusting sleeves in the engine for centring the engine/gearbox assembly and fit if necessary. |

| –

| Before installing gearbox, tie electrical wiring off to one side so that it cannot be trapped between engine and gearbox. |

| –

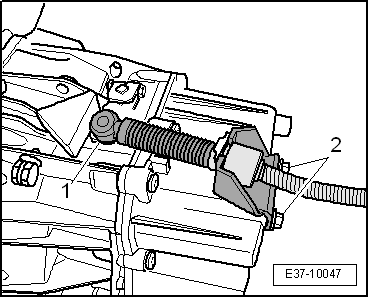

| Lift gearbox high enough to be able to install selector lever cable. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note