Leon Mk1

|

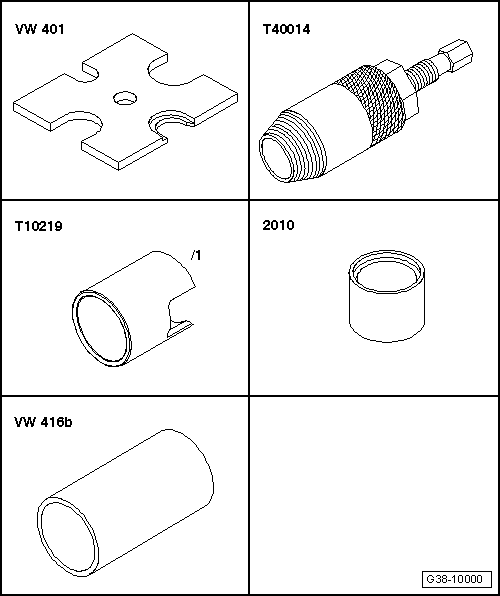

| Special tools and workshop equipment required |

| t | Pressure plate -VW 401-, see equivalent → Anchor |

| t | Seal extractor -T40014- |

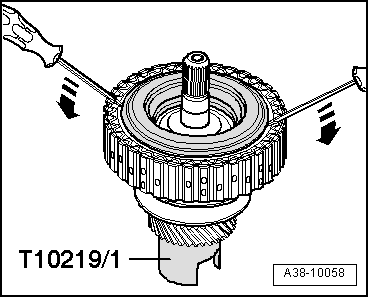

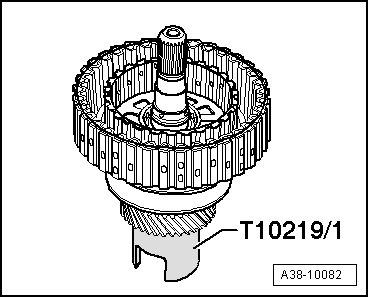

| t | Assembly tool -T10219/1- |

| t | pressure tool -2010- |

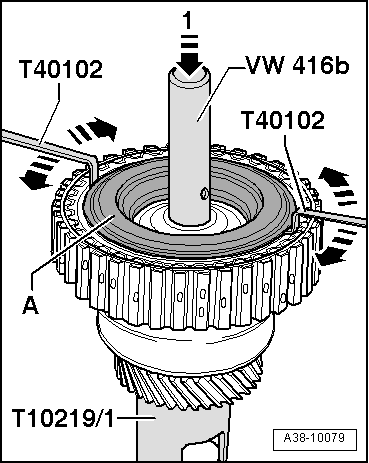

| t | pressure tool -VW 416B- |

| t | pressure tool -T40099- |

| t | Ruler -T40100- |

| t | End measurement plate -T40101- |

| t | Feeler gauge -T40102- |

| t | Digital depth gauge -VAS 6087- |

| t | Wear protective gloves! |

| t | Ice spray |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution