Leon Mk1

|

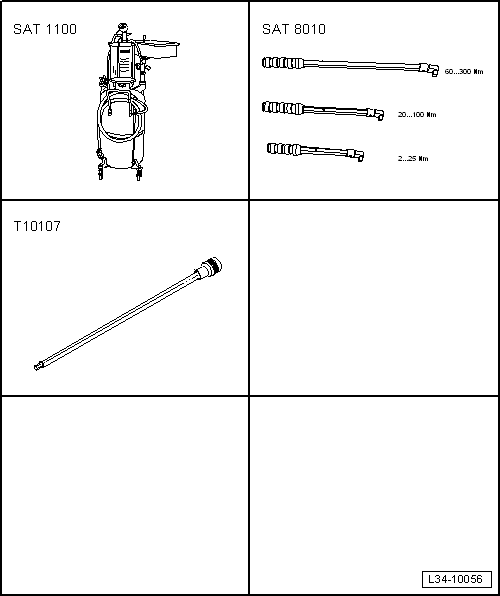

| Special tools and workshop equipment required |

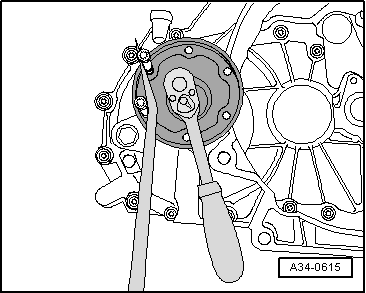

| t | Extractor -SAT 1100-, see equivalent → Anchor |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

| t | Socket and key -T10107- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note |

|

|

|

|

|

|

|

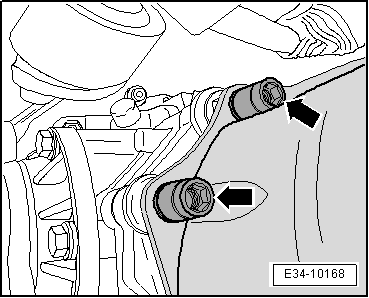

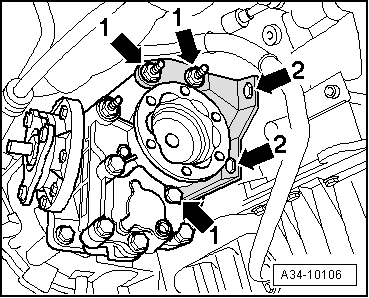

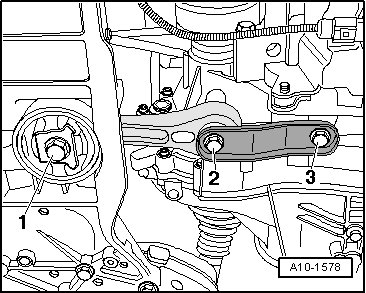

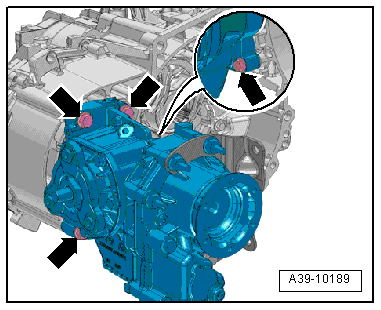

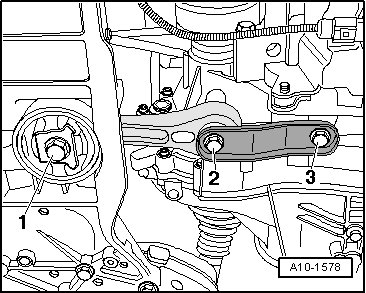

| Component | Nm |

| Heat shield for drive shaft to bevel box | 25 |

Caution

Caution