| –

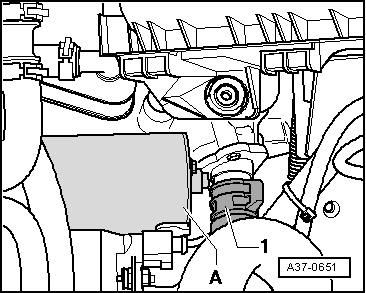

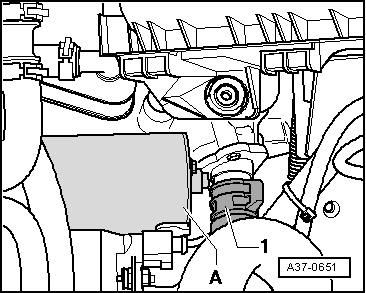

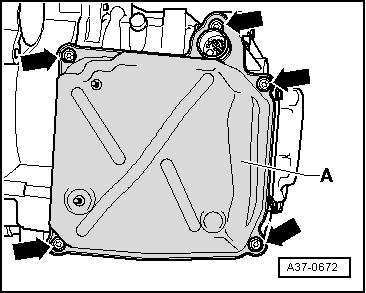

| Release the bayonet lock -1- of the 20-contact connector from the gearbox, by turning and disconnecting. |

| –

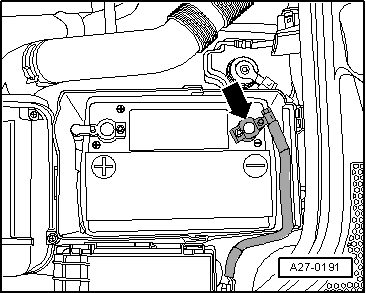

| Touch the vehicle earth with the hand (without gloves) to release static energy. |

WARNING | The person who is going to touch or remove the mechatronic system for the automatic DSG gearbox - J743- should first release static energy by touching an earthed object, e.g. the vehicle earth. |

| The gearbox connector contacts should never be touched with the hands, as this may damage the control unit and, therefore, the Mecatronic unit as a result of a discharge of static energy |

|

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING