Leon Mk1

|

|

|

|

|

Note!

Note!| t | Replace all disks and presses of the clutch that have loose or damaged riveted joints. |

| t | To fit the disk with the corresponding clutch press, check the Spares catalogue and the distinctive lettering of the engine. |

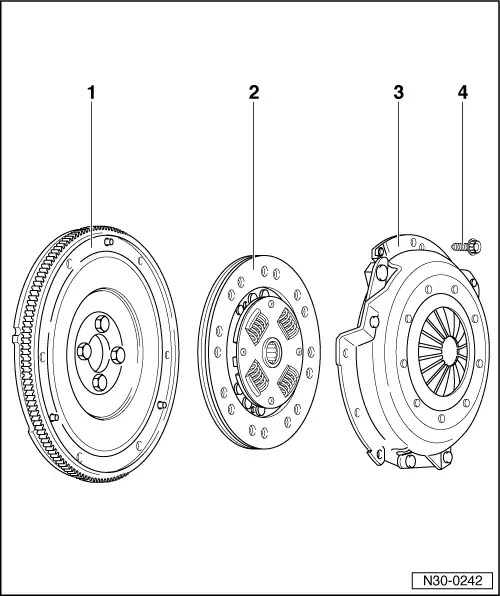

| 1 - | Motorschwungrad |

| q | Make sure the centring pins are properly seated |

| q | The surface of the clutch disk must not be scratched or grooved and should be free from oil and grease |

| q | Removing and refitting → 4 cylinder injection engine (1,0 litres), mechanics; Rep. Gr.13 |

| 2 - | Clutch disk |

| q | Diameter: consult the aside Distinctive Lettering, group correspondence, demultiplications, filling quantities → Chapter |

| q | Note the fitting position: the spring cage must face the clutch press |

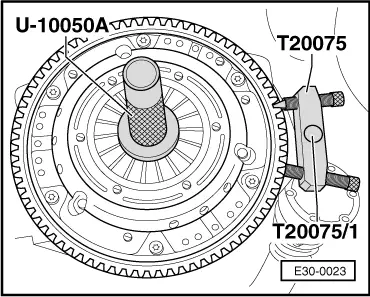

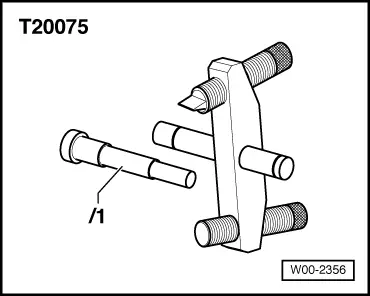

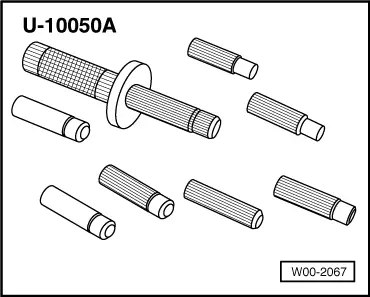

| q | Centring → Fig. |

| q | Light grease the marks so that the declutching bearing can slide easily |

Note!

Note!| Clean the lines of the primary shaft and, with worn clutch disks, the lines on the hub, eliminate corrosion and apply a thin layer of grease. -G 000 100- to the lines of the primary shaft. Then the clutch disk should be moved on the primary shaft from one side to the other until the hub slides gently on the shaft. Eliminate excess grease. |

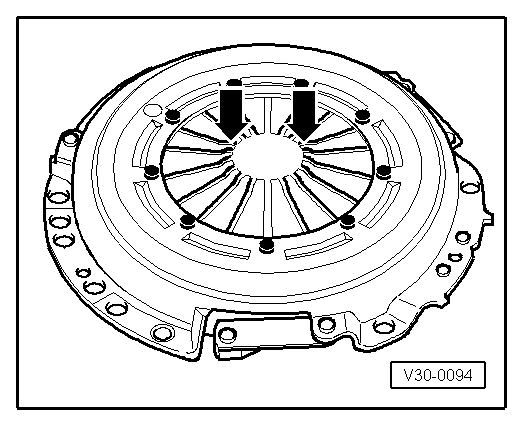

| 3 - | Clutch press |

| q | Removing and refitting → Fig. |

| q | Checking the ends of the diaphragm → Fig. |

Note!

Note!| The clutch presses are greased and protected against corrosion. Only the contact surface can be cleaned, otherwise the useful life of the clutch would be significantly shortened. |

| 4 - | Bolt, 25 Nm |

| q | Loosen and tighten in a cross in various steps |

|

|