Leon Mk1

|

|

|

|

|

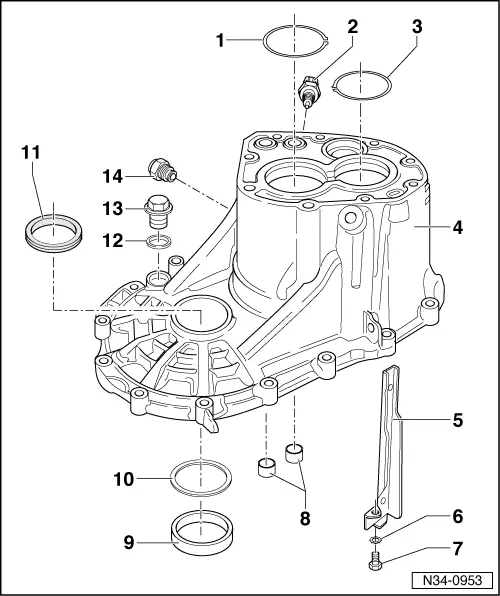

| 1 - | Safety ring |

| q | For the grooved ball bearing of the secondary shaft |

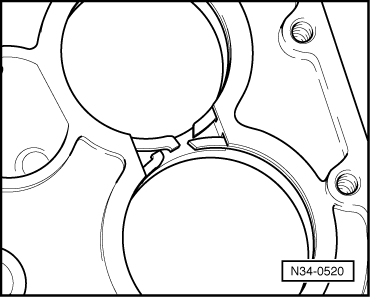

| q | Fitting position → Fig. |

| 2 - | Reverse light switch, 20 Nm |

| q | Screw in applying sealant -D 000 600 A2- |

| 3 - | Safety ring |

| q | For the grooved ball bearing of the secondary shaft |

| q | Fitting position → Fig. |

| 4 - | Gearbox housing |

| 5 - | Oil conductor plate |

| 6 - | Safety washer |

| 7 - | Hexagonal bolt, 10 Nm |

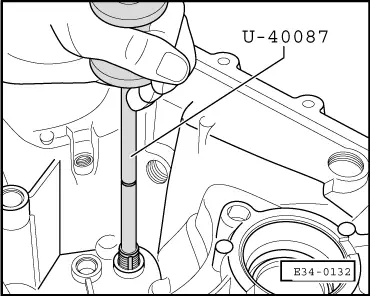

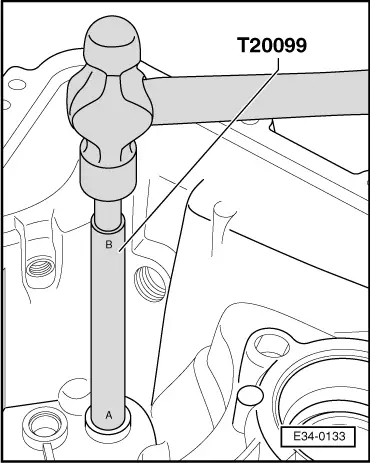

| 8 - | Bearing bushing for control bar |

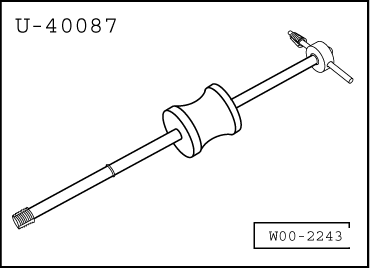

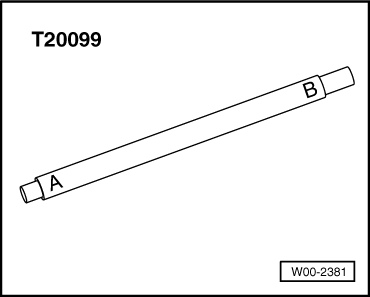

| q | Extract → Fig. |

| q | Fit → Fig. |

| 9 - | External ring of the conic roller bearing |

| q | For the differential |

| q | Removing and refitting → Chapter |

| q | If changed, the differential should be adjusted → Chapter |

| 10 - | Adjustment washer |

| q | For the differential |

| q | Determine the thickness → Chapter |

| 11 - | Seal ring for outlet shaft |

| q | Changing → Chapter |

| 12 - | Seal ring |

| q | Always replace |

| 13 - | Oil pan bolt, 60 Nm |

| 14 - | Retainer bolt for the control bar, 35 Nm |

| q | Screw in applying sealant paste -D 000 600 A2- |

|

|

|

|

|

|