Leon Mk1

|

|

|

|

|

| t | Clutches -K1- and -K3- are snap-fitted one on top of the other. |

| t | Clutch -K1- must only be removed from clutch -K3- for the cleaning or replacement of one of the clutches. |

| t | Disengage clutches -K1- and -K3- → Chapter |

| t | Engage clutches -K1- and -K3- → Chapter |

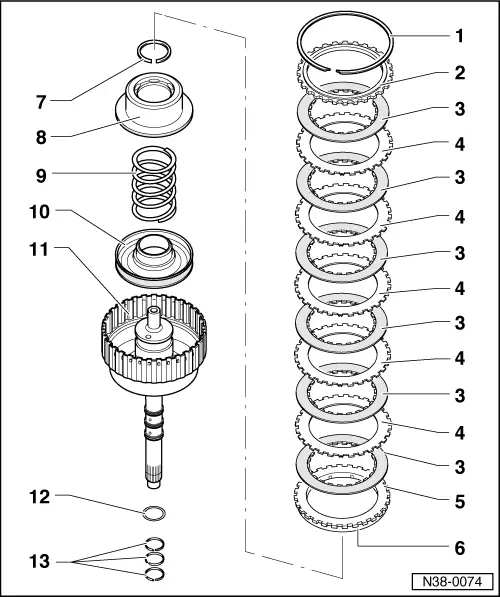

| 1 - | Safety ring |

| q | Different thicknesses |

| q | Mark it after removal and refit in the same position |

| 2 - | Support disk |

| q | Fit the stepped side facing the safety ring |

| 3 - | Inner disk |

| q | Number of disks → Chapter |

| 4 - | Outer disk |

| q | Number of disks → Chapter |

| 5 - | Thrust plate |

| q | Fit it with the ondulated washer facing the piston |

| 6 - | Ondulated elastic washer |

| q | Sealed with the thrust disc → Item |

| 7 - | Safety ring |

| q | Removing and installing → Fig. |

| q | Different thicknesses |

| q | Mark it after removal and refit in the same position |

| 8 - | Piston cover |

| q | The sealing lips are fixed by vulcanisation to the cover |

| q | Before fitting, apply ATF to the sealing lips |

| q | When fitting the cover, turn it slightly |

| q | To remove and fit, press down and fit safety ring → Item |

| 9 - | Spring |

| q | Fit between the piston and the piston cover |

| 10 - | Piston |

| q | The sealing lips are fixed by vulcanisation to the piston |

| q | Before fitting, apply ATF to the sealing lips |

| q | When fitting the piston, turn it slightly |

| 11 - | Clutch housing with turbine shaft |

| q | It has a different height accoridng to the number of outer and inner disks |

| q | There are two different models → Chapter |

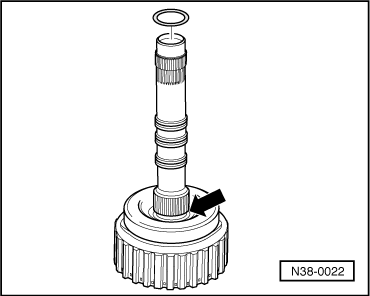

| 12 - | O-ring |

| q | Renew |

| q | Fitting → Fig. |

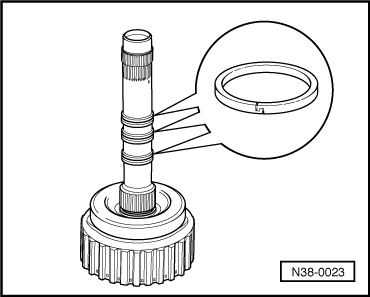

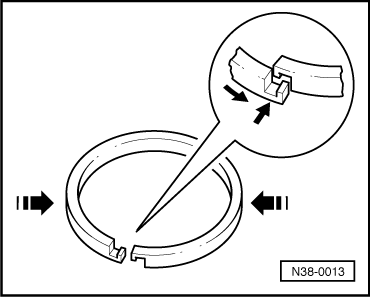

| 13 - | Piston ring |

| q | Check the fitting → Fig. |

| q | Removing and installing → Fig. |

|

|

|

|

|

|

Note!

Note!