Leon Mk1

| Slide box: removal and fitting |

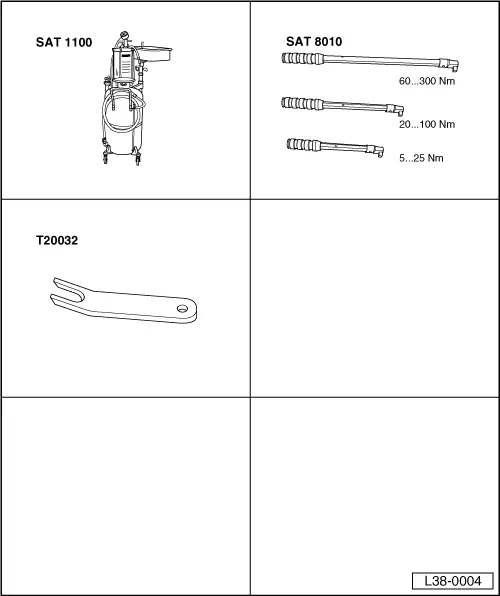

| Special tools and workshop equipment required |

| t | Oil extractor -SAT 1100- |

| t | Torque spanners -SAT 8010- |

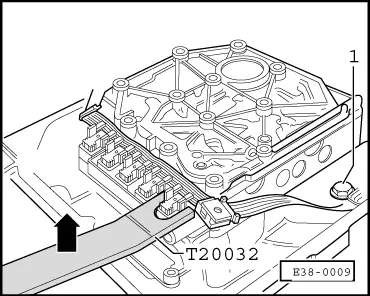

| t | Extractor -T20032- |

Caution

Caution

|

| t | The slide box or conducting plate can be removed and fitted with the gearbox installed in the vehicle. The conducting plate can be removed independently. |

| t | After fitting the ATF sump, check the ATF level and, where necessary, fill up → Chapter |

| t | Dirty or faulty slide boxes must always be replaced. |

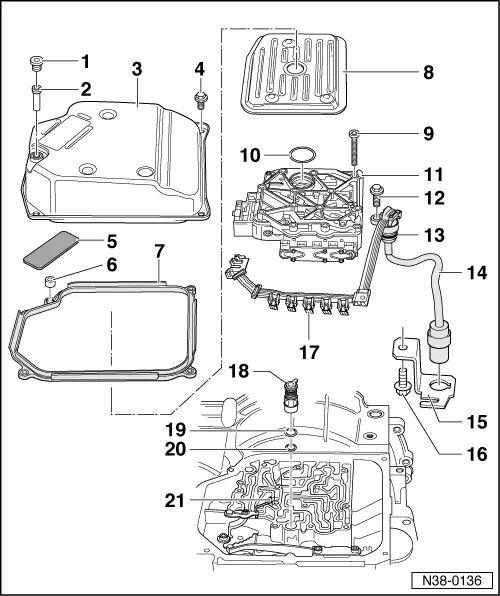

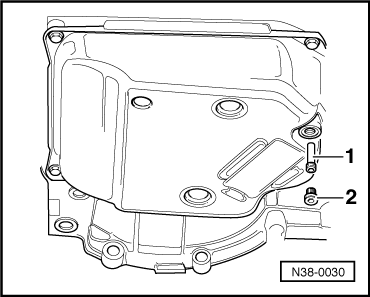

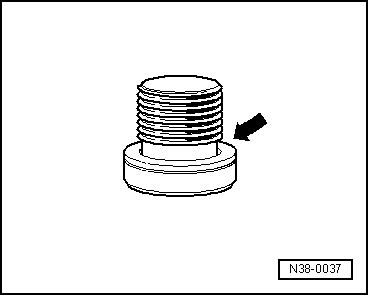

| 1 - | Sealing plug, 15 Nm |

| q | ATF level: checking and filling → Chapter |

| q | Always replace the O ring → Fig. |

| 2 - | Overflow hose |

| q | Remove it to empty the ATF → Fig. |

| q | Screw it in as far as it will go |

| q | ATF level: checking and filling → Chapter |

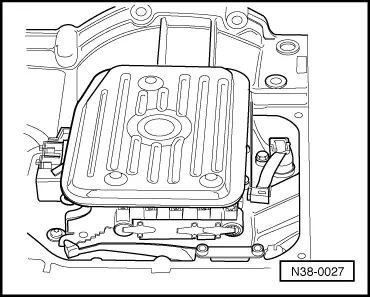

| 3 - | Oil sump |

| 4 - | 12 Nm |

| q | Diagonally tighten the screws for the oil sump at various stages |

| 5 - | Magnet |

| q | Fit it in the oil sump gap |

| 6 - | Spacer |

| q | Fit it in the gasket |

| 7 - | Gasket |

| q | Renew |

| q | Fit the spacers in the gasket |

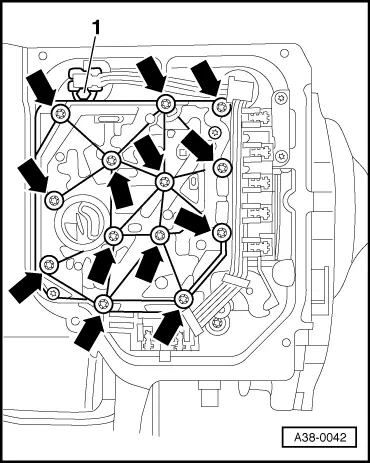

| 8 - | ATF screen |

| q | Fitting → Fig. |

| 9 - | 5 Nm |

| q | Tighten from centre outwards |

| 10 - | Oil seal |

| q | Renew |

| q | Fit in the slide box |

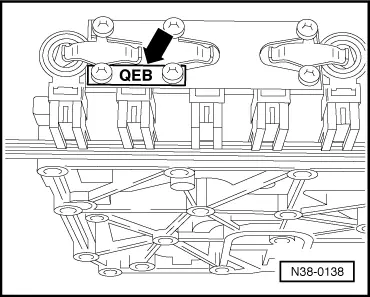

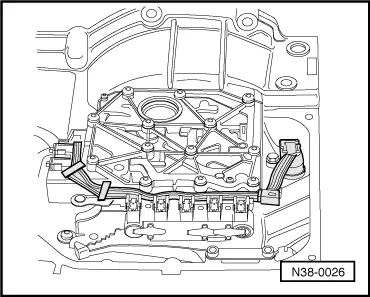

| 11 - | Slide box |

| q | Remove → Fig. |

| q | Location → Fig. |

| q | Identification → Fig. |

| q | Fit the seal → Item |

| q | Start basic adjustments after fitting a new slide box → VAS 5051; Vehicle self-diagnosis |

| 12 - | 10 Nm |

| 13 - | O-ring |

| q | For cable nozzle |

| q | Renew |

| 14 - | Conducting plate |

| q | With nozzle for cables and connector |

| q | ATF temperature sender -G93-, incorporated into the conducting plate |

| q | Can be removed and fitted with the gearbox in place |

| q | Removal → Fig. |

| q | Fitting → Fig. |

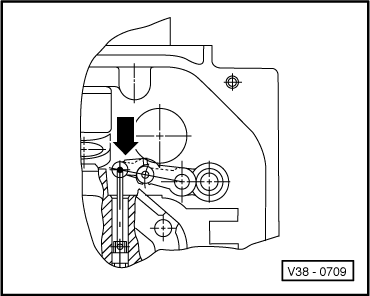

| 15 - | Securing clip |

| q | For the conducting plate connector → Fig. |

| 16 - | 20 Nm |

| 17 - | Connector for solenoid valves |

| q | Remove the solenoid valve connectors using tool -T20032- → Fig. |

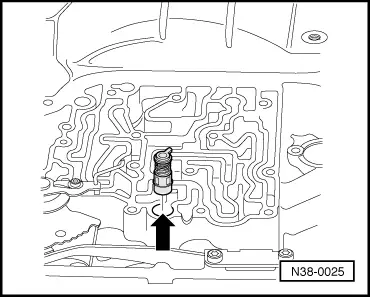

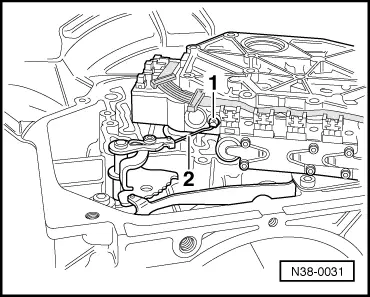

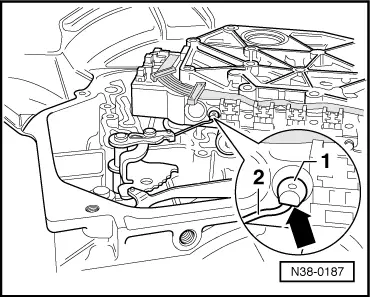

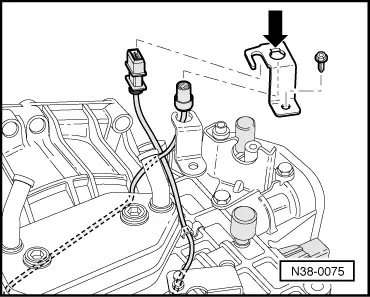

| 18 - | Union plug |

| q | Remove before fitting and removing the free wheel |

| q | Fit so that the tab fits into the cut-out of the gearbox casing → Fig. |

| q | Place the new O ring on the union plugs |

| 19 - | O-ring |

| q | Renew |

| q | Dampen with ATF and fit |

| q | Fit to union plug → Item |

| 20 - | O-ring |

| q | Renew |

| q | Dampen with ATF and fit |

| q | Fit to union plug → Item |

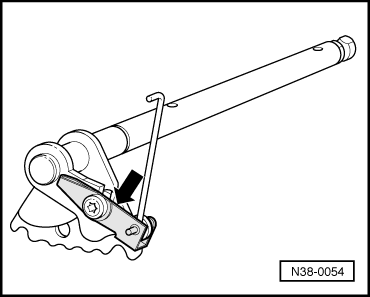

| 21 - | Actioning rod for manual slide |

| q | Unhook → Fig. |

| q | Hook → Fig. |

| q | Adjust → Fig. |

| q | Always replace the actioning rod steel spring and screw for the manual slide → Fig. |

|

|

|

|

|

|

Note!

Note!

|

|

|

|

Note!

Note!

|

|

|

|

Note!

Note!

|

|

|

|

|

|

|

|

Note!

Note!

|

|