Leon Mk1

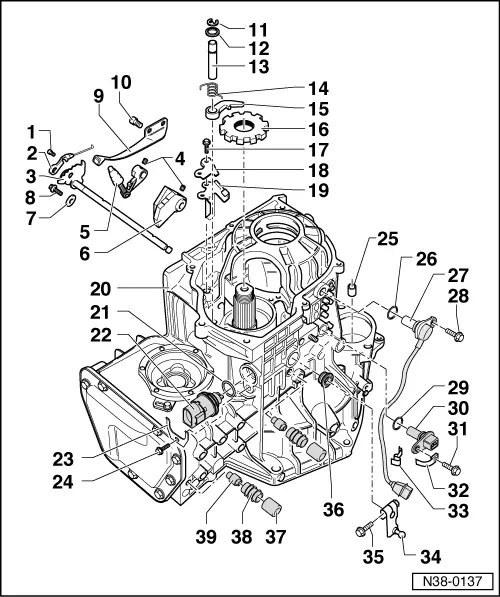

| Parking lock: removal and installation |

| Special tools and workshop equipment required |

| t | Torque spanners -SAT 8010- |

| t | Plunger -U-40027- |

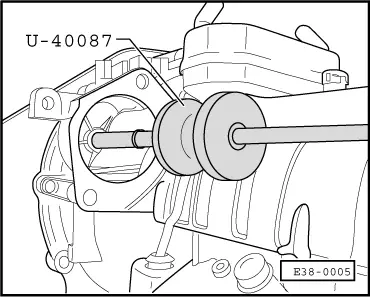

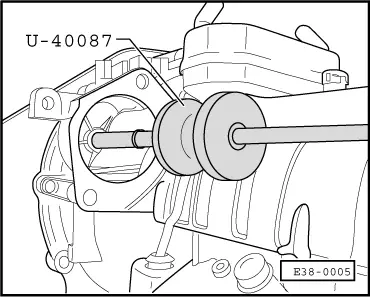

| t | Extractor -U-40087- |

| t | KIT -U-40200 A- |

Note!

Note!| The driven sprocket must be removed to remove and fit the parking lock → Chapter |

| 1 - | 4 Nm |

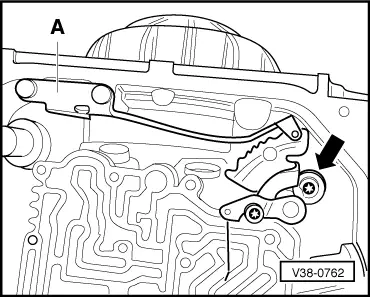

| q | Replace the steel spring and the control bolt on the manual slide control → Fig. |

| 2 - | Manual slide control |

| q | Adjust → Fig. |

| q | Replace the steel spring and the control bolt on the manual slide control → Fig. |

| 3 - | Selector rod with connection piece |

| q | Removing and installing → Fig. |

| 4 - | Support sleeve |

| q | Removing and installing → Fig. |

| 5 - | Meshing lever |

| q | Position it with the selector rod and meshing lever |

| 6 - | Meshing piece |

| q | Position it with the selector rod and meshing lever |

| 7 - | Safety washer |

| 8 - | 10 Nm |

| 9 - | Control piece spring |

| 10 - | 10 Nm |

| 11 - | Safety ring |

| q | Renew |

| q | Fit it only on rods with recesses for safety rings |

| 12 - | Washer |

| 13 - | Shafts for safety levers |

| q | Secure using the safety rings and the crown pinion shaft bearing cover |

| 14 - | Recuperation spring |

| q | Fit → Fig. |

| 15 - | Securing lever |

| q | Fit with the recuperation spring → Fig. |

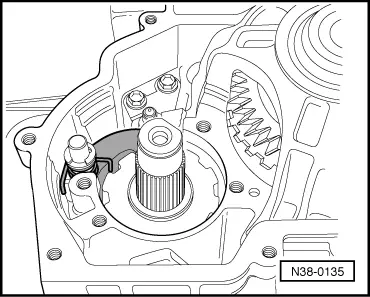

| 16 - | Parking lock sprocket |

| q | The rounded side must face the toothing on the crown pinion shaft |

| 17 - | 14 Nm |

| 18 - | Support tab |

| q | Assembly → Fig. |

| 19 - | Guide plate |

| q | Position before the support tab → Fig. |

| 20 - | Gearbox casing |

| q | To disarm the parking lock, it is not necessary to remove the pinion wheel |

| 21 - | O-ring |

| q | Renew |

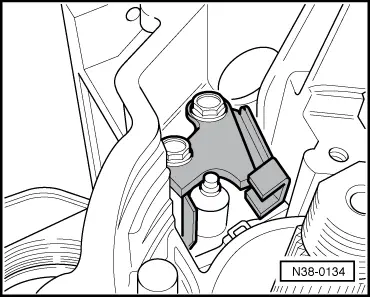

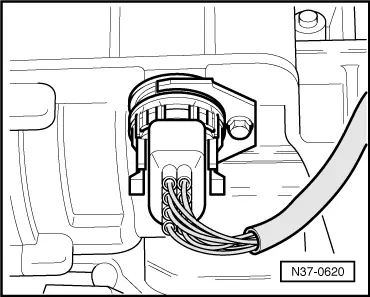

| 22 - | Multi-function switch -F125- |

| q | Removing and installing → Fig. |

| q | Check on the vehicle by self-diagnosis → VAS 5051; Vehicle self-diagnosis |

| 23 - | Support |

| q | For multi-function switch |

| 24 - | 10 Nm |

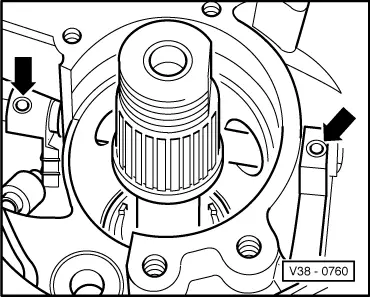

| 25 - | Starter motor bush bearing |

| q | Remove → Fig. |

| q | Fitting → Fig. |

| 26 - | O-ring |

| q | Renew |

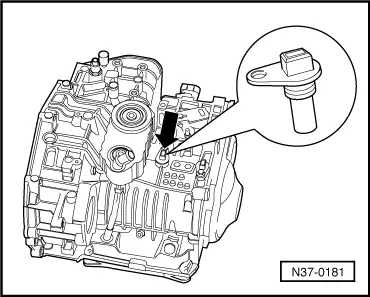

| 27 - | Road speed sender -G68- |

| q | Removing and installing → Fig. |

| q | Check on the vehicle by self-diagnosis → VAS 5051; Vehicle self-diagnosis |

| 28 - | 10 Nm |

| 29 - | O-ring |

| q | Renew |

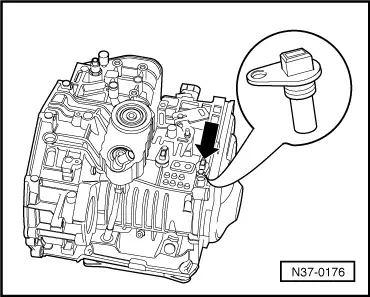

| 30 - | Gearbox rev. speed sender -G38- |

| q | Removing and installing → Fig. |

| q | Check on the vehicle by self-diagnosis → VAS 5051; Vehicle self-diagnosis |

| 31 - | 10 Nm |

| 32 - | Support |

| q | For the speed sender cable |

| q | Secure using the bolt → Item |

| 33 - | Securing clip |

| q | For the speed sender cable |

| 34 - | Lever |

| q | For connecting shaft |

| 35 - | 10 Nm |

| 36 - | Selector rod oil seal |

| q | Fit with tool -U-40200/15- |

| 37 - | Breather cap |

| 38 - | Breather piece |

| 39 - | Breather pipe |

| q | Remove with pliers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|