Leon Mk1

|

|

|

|

|

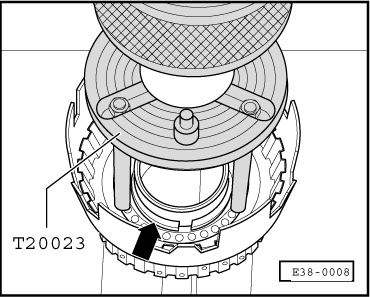

| t | The reverse gear clutch -K2- must only be removed for cleaning. |

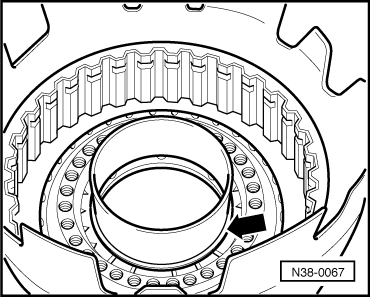

| t | When removing the clutch, do not damage the ball valve -arrow-. |

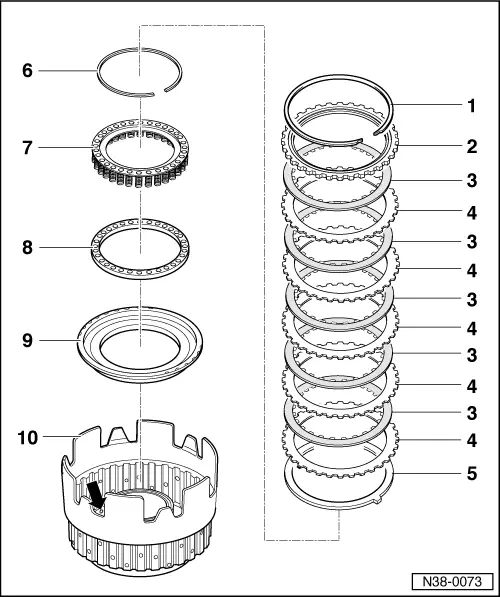

| 1 - | Safety ring |

| q | Mark it after removal and refit in the same position |

| q | Different thicknesses |

| 2 - | Support disk |

| q | Fit the flat side facing the inner disks |

| q | Different thicknesses |

| 3 - | Inner disk |

| q | Number of disks → Chapter |

| q | Before installing, leave in ATF 15 minutes |

| 4 - | Outer disk |

| q | Number of disks → Chapter |

| 5 - | Ondulated elastic washer |

| 6 - | Safety ring |

| q | Removing and installing → Fig. |

| q | Fitting position → Fig. |

| 7 - | Support tab |

| q | With springs |

| q | Fitting position → Fig. |

| 8 - | Springed support ring |

| 9 - | Piston |

| q | The sealing lips are fixed by vulcanisation to the piston |

| q | Before fitting, apply ATF to the sealing lips |

| q | When fitting the piston, turn it slightly |

| 10 - | Clutch housing |

|

|

Note!

Note!