Leon Mk1

|

|

|

|

|

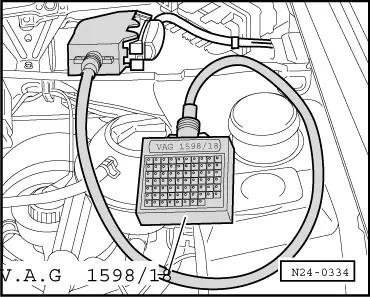

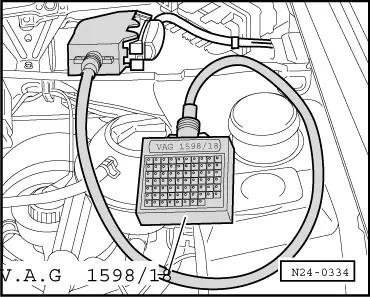

| Test box -V.A.G 1598/18-, socket | ||

| 19 + 39, 39 + 45, 19 + 45 | ||

| Specification: ∞ Ω |

|

|

|

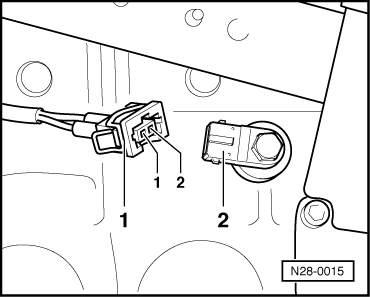

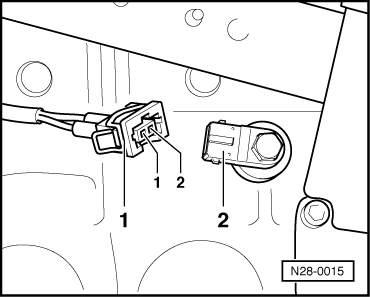

| Contact | Test box -V.A.G 1598/18-, socket | |

| 1 | 39 | |

| 2 | 19 | |

| Wire resistance: 1,5 Ω max. | ||

|

|

|

|

|

|

| Test box -V.A.G 1598/18-, socket | ||

| 19 + 39, 39 + 45, 19 + 45 | ||

| Specification: ∞ Ω |

|

|

|

| Contact | Test box -V.A.G 1598/18-, socket | |

| 1 | 39 | |

| 2 | 19 | |

| Wire resistance: 1,5 Ω max. | ||

|