Leon Mk1

|

| Special tools and workshop equipment required |

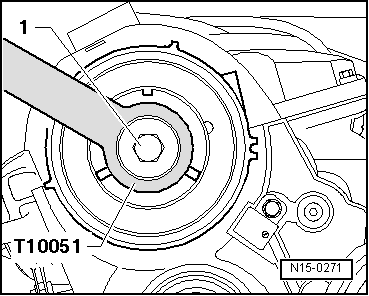

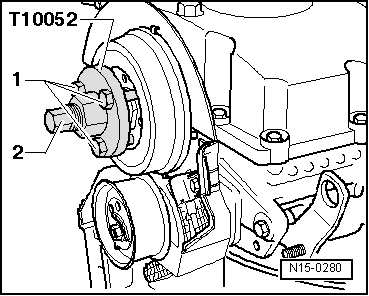

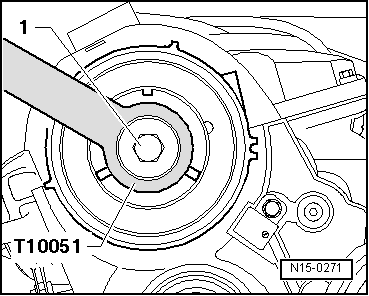

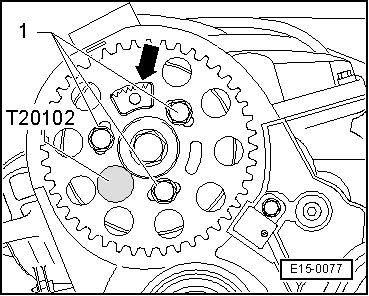

| t | Counterhold tool -T10051- |

| t | Extractor -T10052A- |

| t | Torque wrench -SAT 8010- |

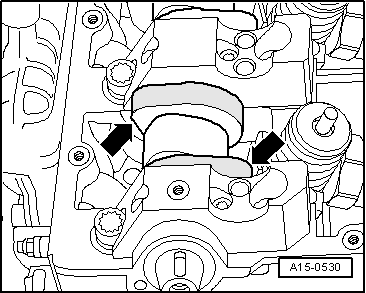

| t | Silicone sealant → Spare parts catalogue |

|

|

|

|

|

Note

Note

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|