Leon Mk1

|

| 1 - | Bearing shells 1, 2, and 4 |

| q | For bearing cap without oil groove. |

| q | For cylinder block with oil groove. |

| q | Do not interchange used bearing shells (mark) |

| 2 - | 65 Nm + 90° (1/4 turn) |

| q | 10 off |

| q | Renew |

| q | When measuring radial clearance, tighten to 65 Nm but do not turn further |

| 3 - | Bearing cap |

| q | Bearing cap 1: Pulley side: |

| q | Bearing cap 3 with rebates for the thrust washer |

| q | Fitting position: Bearing shell retaining lugs in cylinder block and bearing caps must align. |

| 4 - | Bearing shell 3 |

| q | For bearing cap without oil groove. |

| q | For cylinder block with oil groove. |

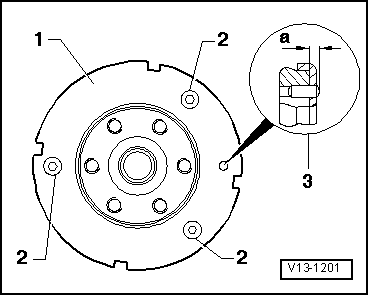

| 5 - | Generator wheel: |

| q | For engine speed sender -G28- |

| q | Only engine code AMF, BNM, BNV |

| q | If this is damaged, replace it |

| q | Always renew sender wheel if bolts have been loosened |

| q | Removing and installing → Fig. |

| 6 - | 10 Nm + 90° (1/4 turn) |

| q | Renew |

| q | Only engine code AMF, BNM, BNV |

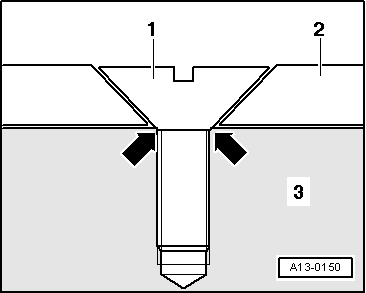

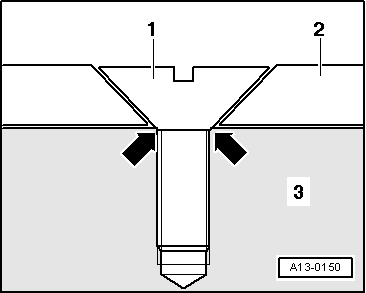

| 7 - | Locking pin |

| q | Check the extension of the pin over the crankshaft → Fig. |

| q | Only engine code AMF, BNM, BNV |

| 8 - | Crankshaft |

| q | New axial play: 0.07... 0.17 mm; Wear limit: 0.37 mm |

| q | Check radial clearance with Plastigage |

| q | New radial play: 0.03... 0.08 mm; Wear limit: 0.17 mm |

| q | Do not rotate crankshaft when checking radial clearance. |

| q | Crankshaft dimensions → Chapter |

| 9 - | Thrust washer |

| q | For cylinder block, bearing 3 |

Note

Note |

|

|

|