Leon Mk1

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

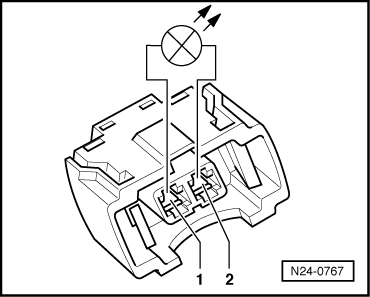

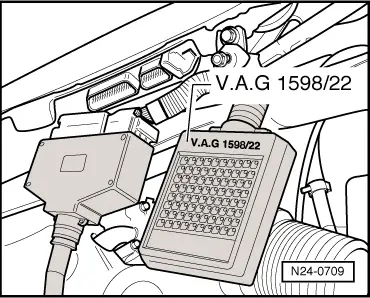

| Cyl. | Injector connector, contact | Test box -V.A.G 1598/22-, socket |

| 1 | 2 | 79 |

| 2 | 2 | 59 |

| 3 | 2 | 73 |

| 4 | 2 | 65 |

| Specification: 1.5 Ω max. | ||

|

|

|