| –

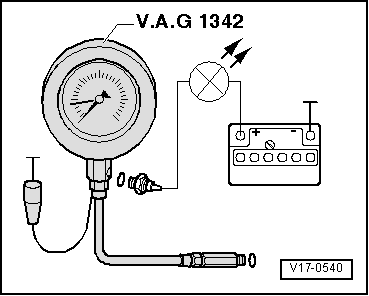

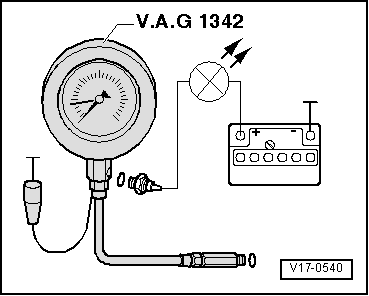

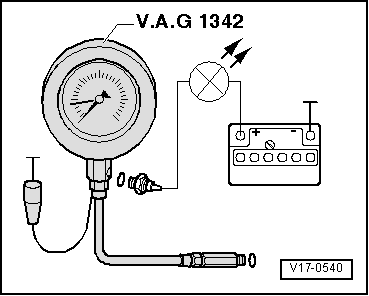

| Remove the 0.5 bar oil pressure switch (green insulation) and screw it into the checker. |

| –

| Screw the checker into the cylinder head, at the site of the oil pressure switch. |

| –

| Ground the brown cable of the checker (-). |

| –

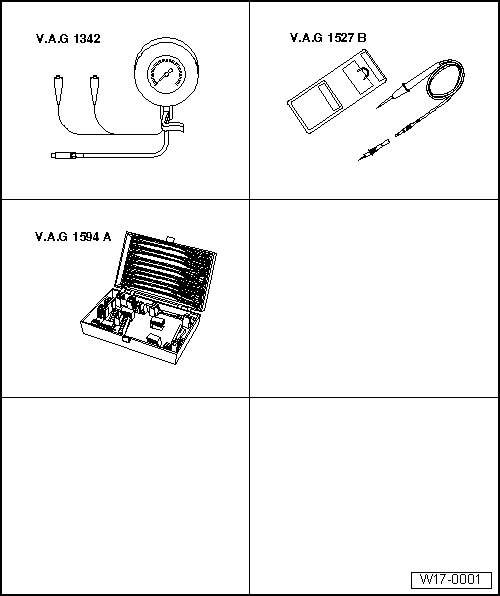

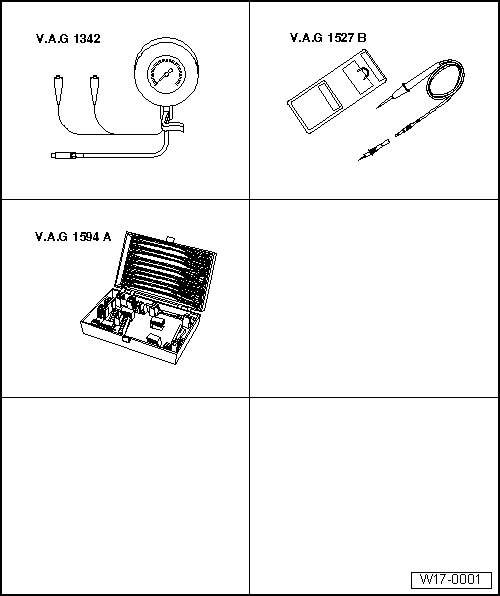

| Using auxiliary cables -V.A.G 1594 A-, connect diode lamp -V.A.G 1527 B- to the positive battery terminal (+) and to the oil pressure switch. The lamp should not flash. |

| –

| If the diode flashes, renew the 0.5 bar oil pressure switch. |

| If the lamp does not flash: |

| –

| Start up the engine and slowly rev up. |

|

| Between 0.3...0.6 bar of pressure the lamp should flash. If not, renew the 0.5 bar oil pressure switch. |

| –

| Continue to rev up. At 2000 rpm, with the oil at a temperature of 80 °C, the oil pressure should be at a minimum of 2.0 bar. |

|

|

|

Note!

Note!

Note!

Note!