| –

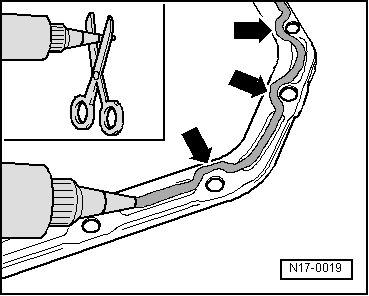

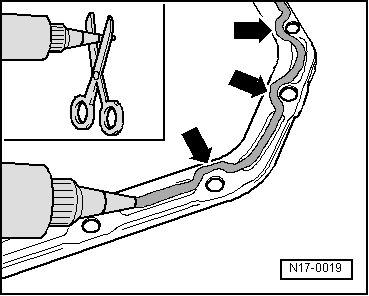

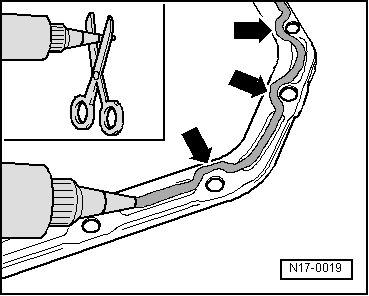

| Cut the nozzle of tube at the front mark (approximate diameter of the nozzle: 3 mm). |

| –

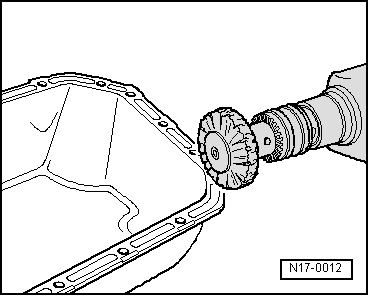

| Apply the silicon-based sealant to the clean contact surface of the oil sump, following the example in the illustration. The strip should: |

| t

| have a thickness of 2 … 3 mm |

| t

| pass by the bolt orifices, on the inner side -arrows-. |

Note! | The sealant strip should not be any thicker, to avoid penetration of excessive sealant in the oil sump, obstructing the strainer of the oil intake hose. |

| –

| Immediately install the oil sump and lightly tighten the securing bolts. |

| –

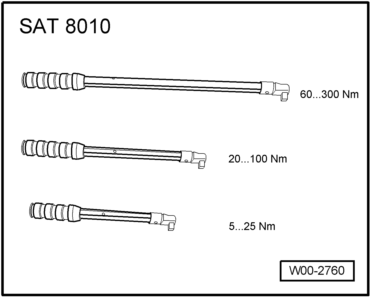

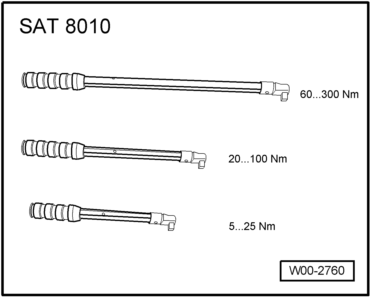

| Tighten the oil sump securing bolts to the par of 15 Nm. |

Note! | After installation of the oil sump, the sealant should dry for approximately 30 minutes. After this time, oil fill-up may begin. |

|

|

|

Note!

Note!

Note!

Note! Note!

Note!

Note!

Note!

Note!

Note! Note!

Note!