| –

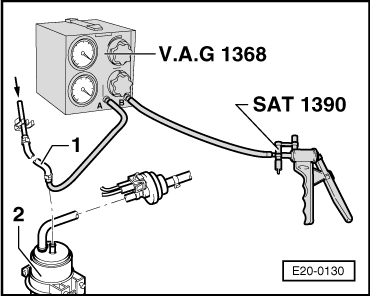

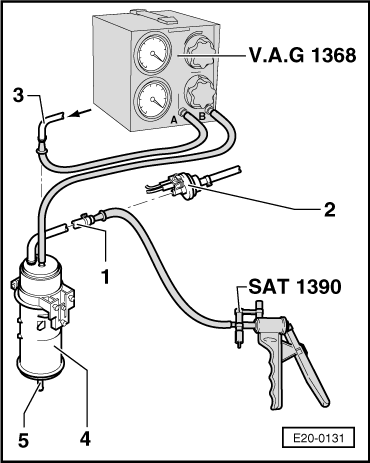

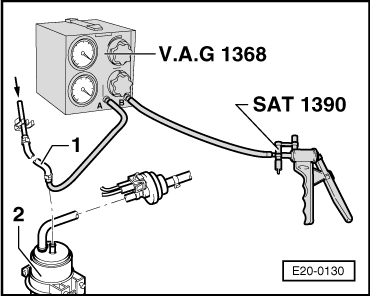

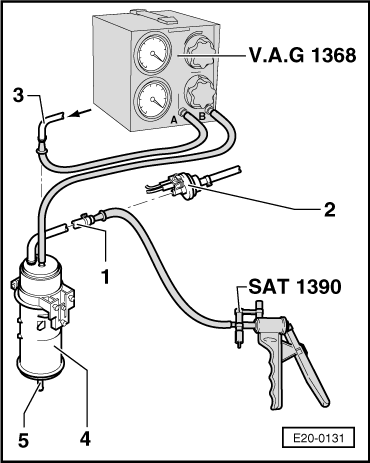

| Pull fuel tank breather hose -1- from the activated charcoal filter -2-. |

| –

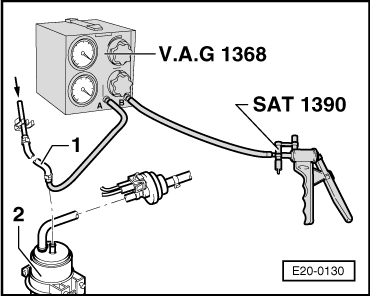

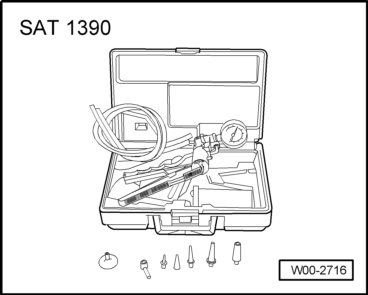

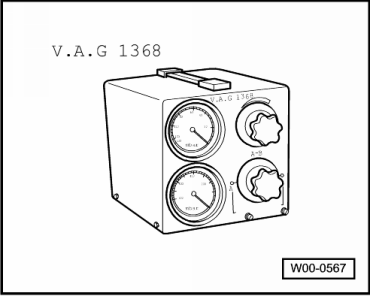

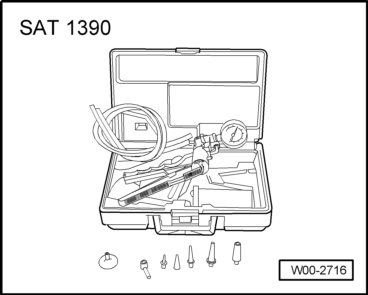

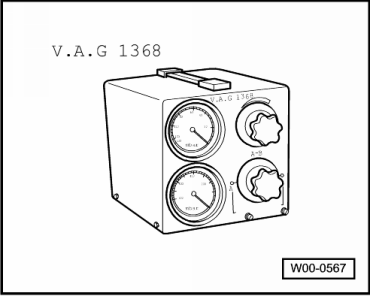

| Using the illustration as a reference, connect hand vacuum pump -V.A.G 1390- and vacuum tester -V.A.G 1368- to hose -1-. |

| –

| Set vacuum tester to position -A/B-. |

| –

| Unscrew fuel filler cap. |

| –

| Operate hand vacuum pump -SAT 1390- several times. Vacuum must not build up. |

| –

| Check gravity/overload valve → Item. |

| –

| Check pipe/hose -1- from fuel tank for blockage. |

| If vacuum does not build up: |

| –

| Refit fuel filler neck. |

| –

| Operate hand vacuum pump several times. Without creating vacuum. |

Note! | If the fuel level in the tank is low, the hand vacuum pump must be operated at least 20…30 times. |

| –

| Replace fuel tank filler neck. |

|

|

|

Note!

Note!

Note!

Note!