Note! | t

| Only remove the new cylinder head gasket from its packaging immediately prior to installing. |

| t

| Handle the new gasket with extreme care. Damaging will lead to leaks. |

| –

| Place a clean cloth in cylinders so that no dirt or emery particles can get between cylinder wall and piston. |

| –

| Carefully clean cylinder head and cylinder block sealing surfaces. Ensure that no scoring or scratches are formed (when using emery/abrasive cloth/paper the grade must not be less than 100). |

| –

| Carefully remove metal particles, emery remains and cloths. |

| –

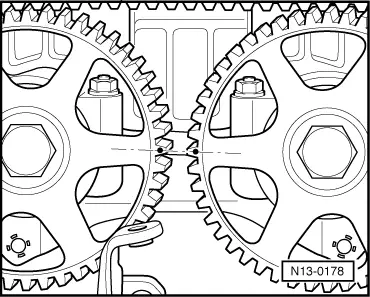

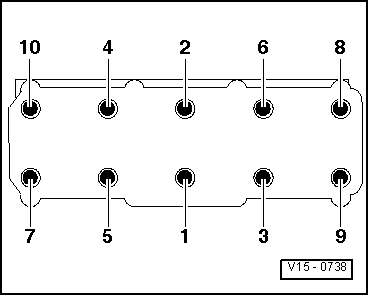

| Turn crankshaft so that No. 1 cylinder piston is positioned at top-dead-centre (TDC), then turn crankshaft back slightly. |

|

|

|

Note!

Note!

Note!

Note!