Leon Mk1

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

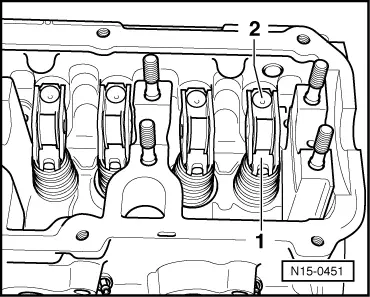

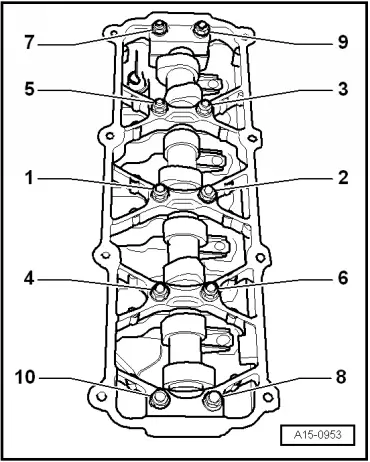

| Components: | Nm | |

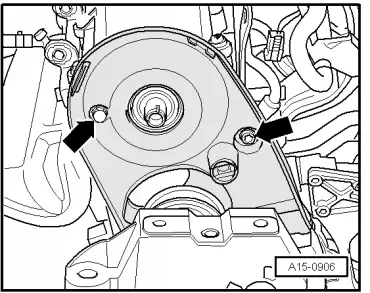

| Rear notched belt guard | M6 | 10 → Remark |

| on cylinder head | M8 | 23 → Remark |

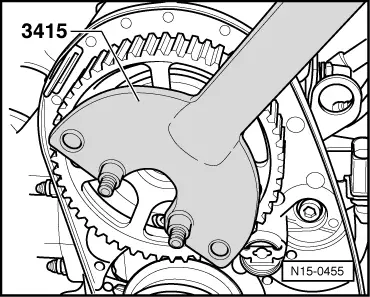

| Camshaft gear to camshaft | 100 | |

| Conductor frame to cylinder head | 23 | |

|

WARNING

WARNING Caution

Caution