| –

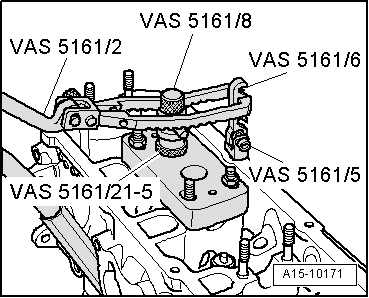

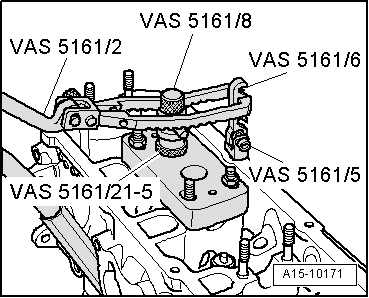

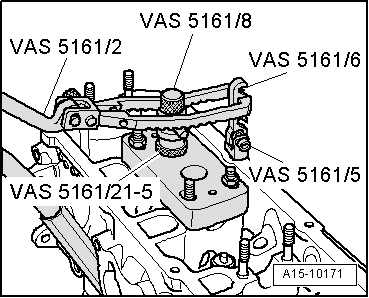

| Screw snap-in device -VAS 5161/6- with engaging forks -VAS 5161/5- into guide plate -VAS 5161/20-. |

| –

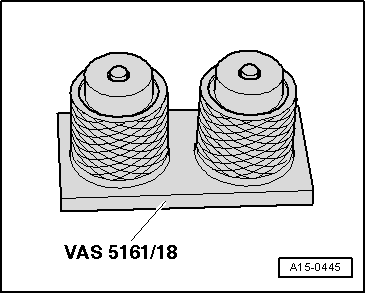

| Slide the knurled spacer ring (height: 8,4 mm) -VAS 5161/17- onto the assembly cartridge -VAS 5161/8-. |

| –

| Attach pressure fork -VAS 5161/2- to snap-in device -VAS 5161/6- and push assembly cartridge down. |

| –

| At the same time, turn knurled screw of assembly cartridge clockwise until tips engage in valve cotters. |

| –

| Move the knurled bolt lightly from side to side. In this way the valve cotter pins are separated by the pressure and fit into the cartridge. |

| –

| Remove the assembly cartridge with a knurled spacer ring, valve head and valve spring. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note