| –

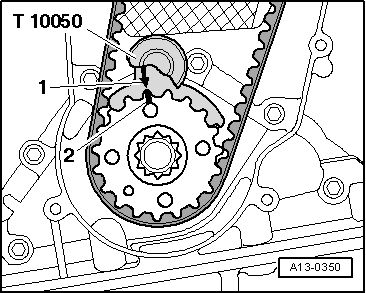

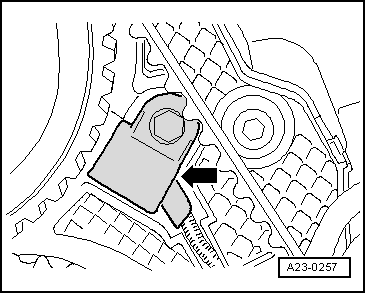

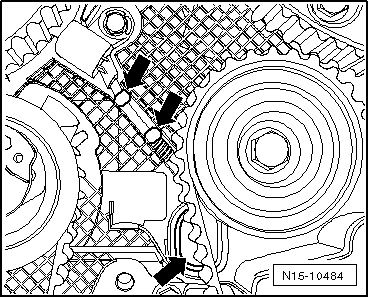

| Release the latches with a screwdriver and remove the cover from the repair opening -Arrows-. |

| –

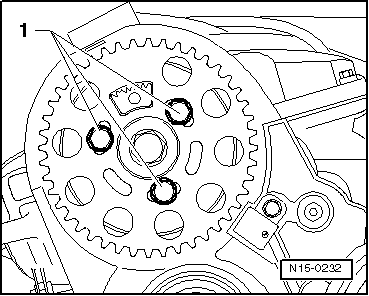

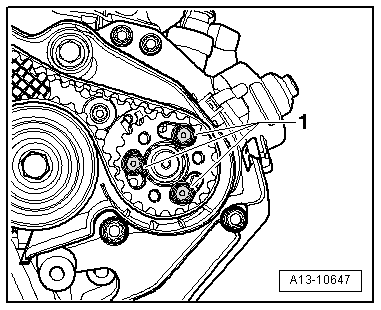

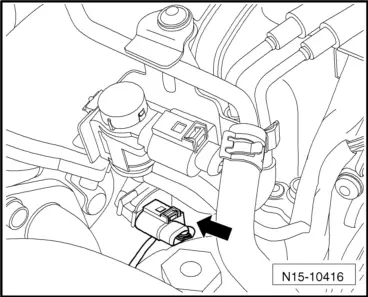

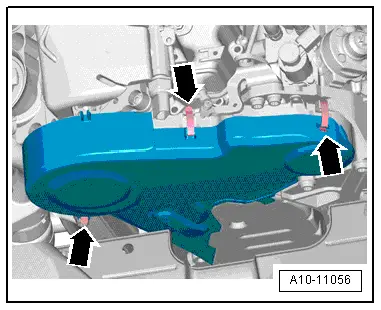

| Remove the Hall sender -G40- from the cylinder head and guide its connection through the opening in the toothed belt cover provided for repair purposes. |

| Installation is in the reverse sequence of removal. In the process, note the following: |

| t

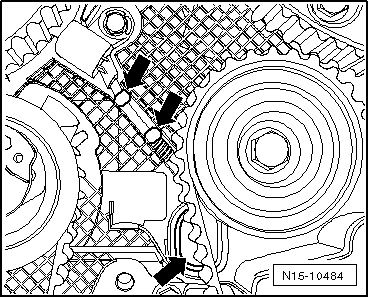

| Cover the toothed belt cover opening, which is provided for repair purposes, with a rubber cover. See → Spare parts catalogue. |

| –

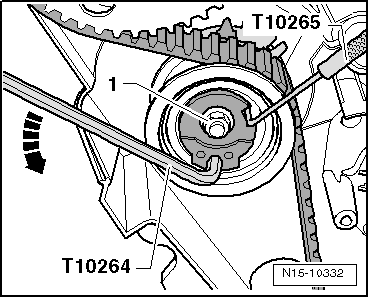

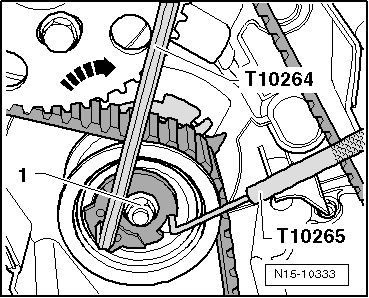

| Fit the toothed belt and set the valve timings → Anchor. |

|

|

|

Note

Note