| –

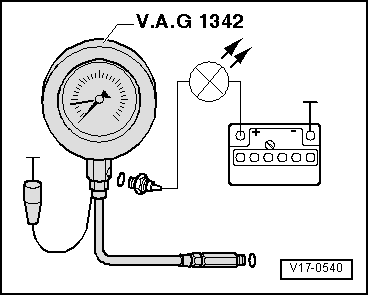

| Remove the oil pressure switch -F1-, and screw it into the tester. |

| –

| Screw tester into the cylinder head in place of the oil pressure switch. |

| –

| Connect the brown wire of the tester to earth (-). |

| –

| Connect the voltage tester -V.A.G 1527B- with the auxiliary cables from the measuring tool set -V.A.G 1594C- to positive of battery (+) and to the oil pressure switch. |

| –

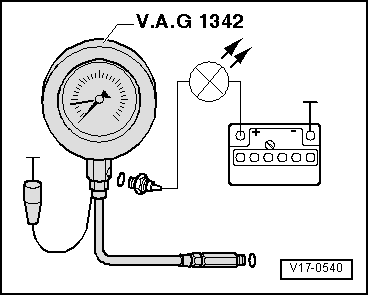

| If the LED lights up, replace oil pressure switch -F1-. |

| If the LED does not light up: |

| –

| Start engine and slowly increase engine speed. The LED should light up between 0.3 ..0.7 bar; if not replace oil pressure switch. |

| –

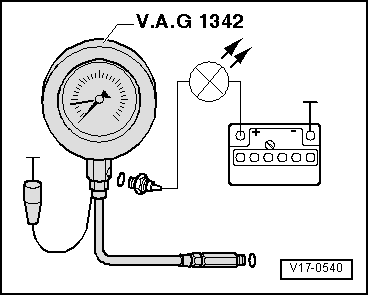

| Increase engine speed further. At 2000 rpm and with the oil temperature at 80 °C, the oil pressure should be 2.0 bar at least. |

| At higher engine speed the oil pressure must not exceed 7.0 bar. |

|

|

|

Note

Note

Note

Note