Leon Mk1

| Compressor: removing and fitting |

| Special tools and workshop equipment required |

| t | Pliers for clamps -VAS 5024A- |

| t | Torque wrench (5...50 Nm) -V.A.G 1331- |

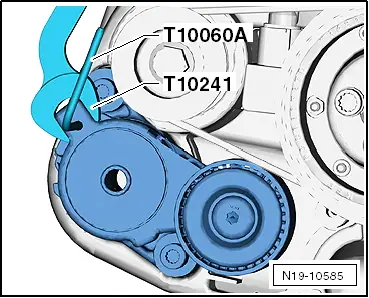

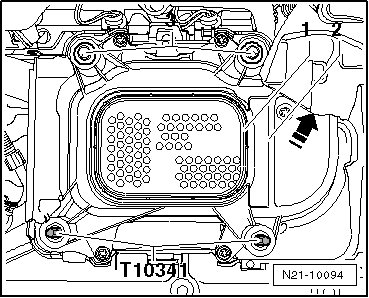

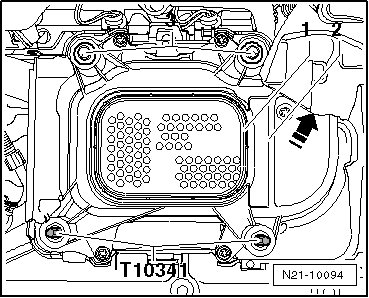

| t | Guide pins -T10341- |

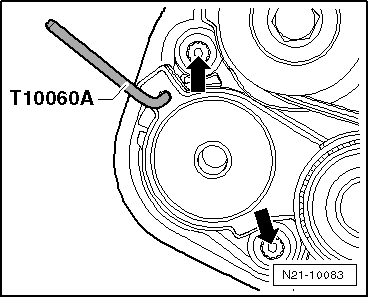

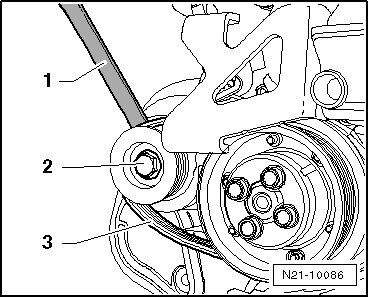

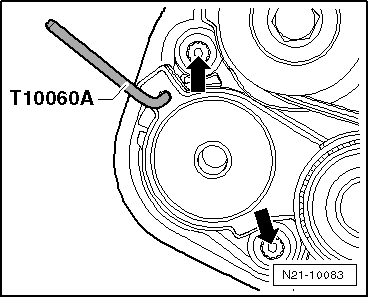

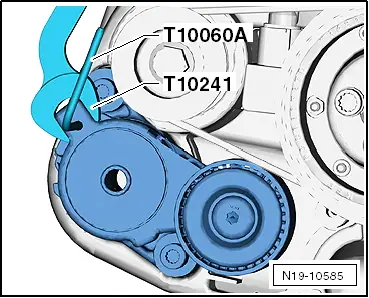

| t | Locking pin -T10060 A- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Caution

Caution