| t

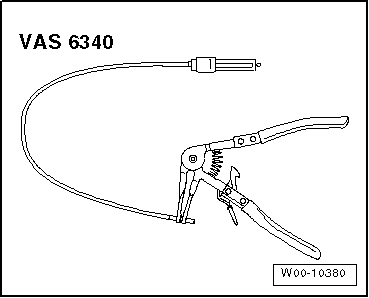

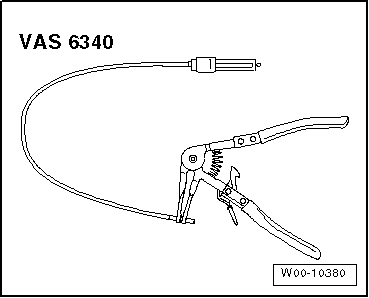

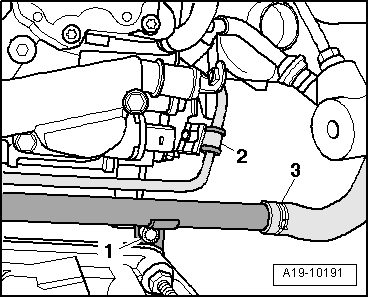

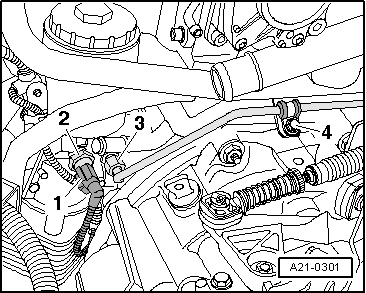

| Pliers -VAS 6340-, see equivalent → Anchor |

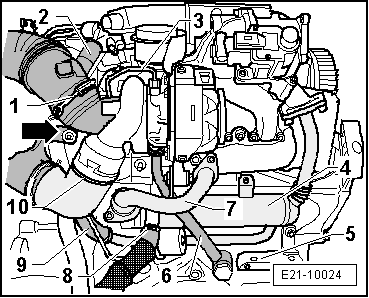

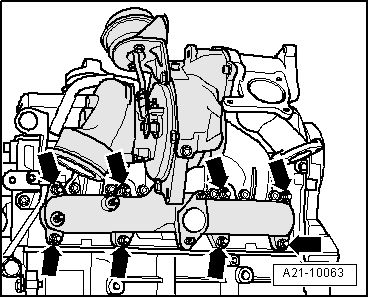

Caution | If a mechanical fault is detected on the turbocharger, for example, a broken blade wheel, changing the turbocharger is not enough. To avoid subsequent damage, carry out the following operations: |

| t

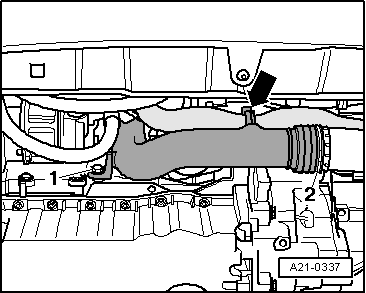

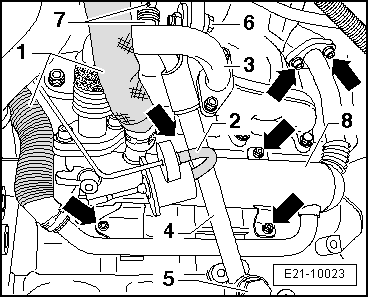

| Ensure that the air filter housing, the cartridge and the vacuum hoses are not dirty. |

| t

| Ensure that there are no foreign bodies in the supercharger air circuit and the intercooler. |

| If foreign bodies are found in the supercharger air system, the supercharger air circuit should be cleaned and, if necessary, the intercooler replaced. |

|

|

|

|

Note

Note Note

Note

Caution

Caution WARNING

WARNING