| –

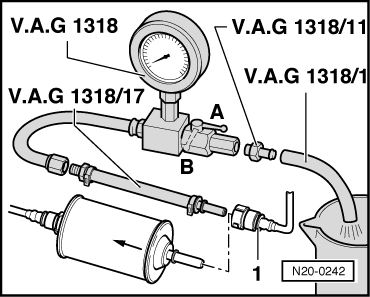

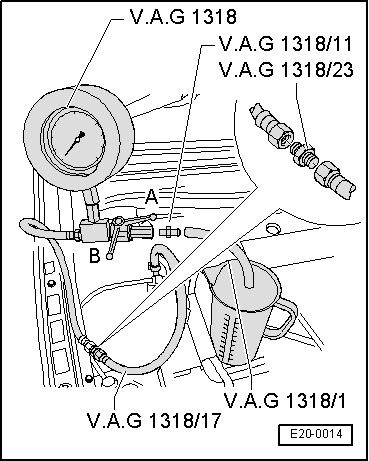

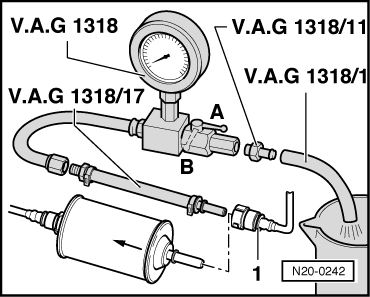

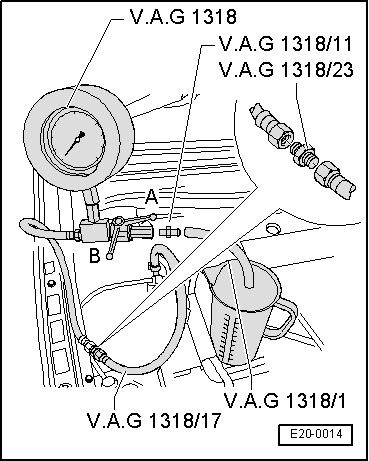

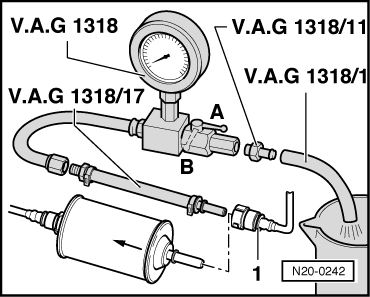

| Attach to the supply hose the pressure gauge -V.A.G 1318- with adaptor/17. |

| If the minimum flow is now reached: |

| –

| Replace the fuel filter. |

| If the minimum flow is still not reached: |

| –

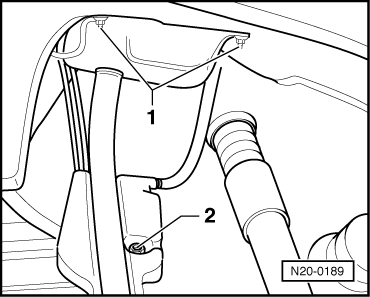

| Remove the fuel supply unit and check the filter for dirt. |

| Only if no fault has been found until now: |

| –

| Replace the fuel supply unit. |

| If the fuel flow has been reached, but, despite this, there seems to be a fault in the fuel supply (e.g. a momentary failure in fuel supply): |

| –

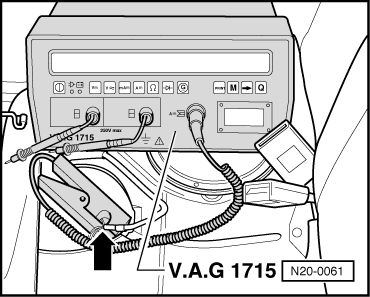

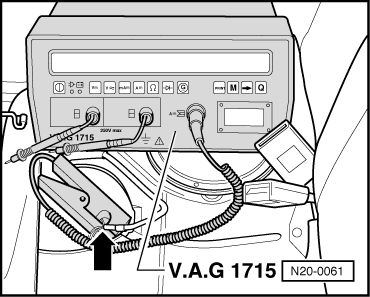

| Measure the voltage consumption of the fuel pump, as follows: |

| –

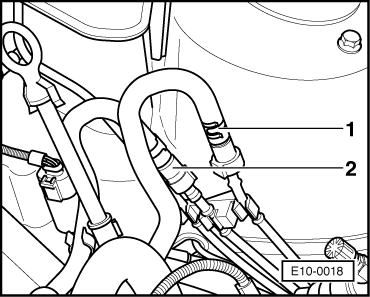

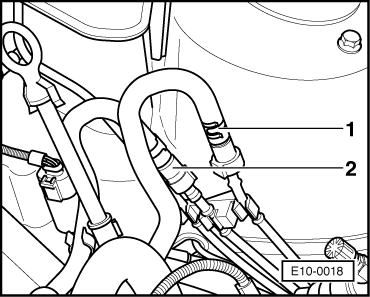

| Reattach the fuel lines that were removed. |

|

|

|

Note!

Note!

Note!

Note!