| l

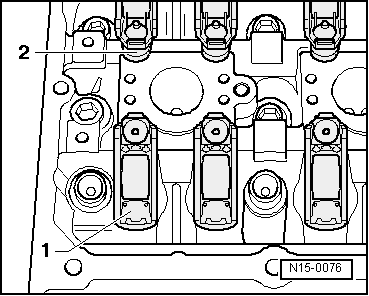

| The pistons must not be positioned at TDC. |

| l

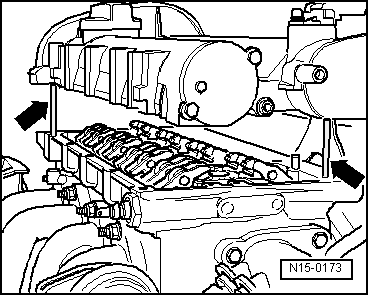

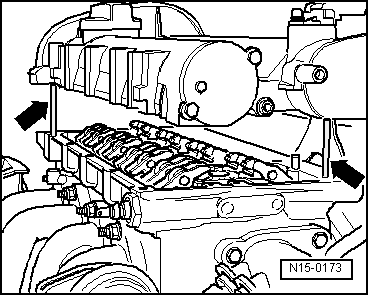

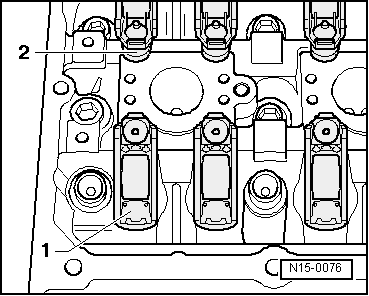

| The camshafts should be locked using the counterhold -T10016- in the existing locking spaces in the camshaft housing, and secured to prevent turning. |

| –

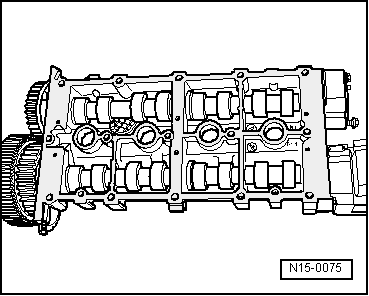

| Remove sealant remnants on cylinder head and camshaft housing with a commercially available flat scraper. |

| –

| Prevent dirt and sealant remnants from entering cylinder head. |

| –

| Clean contact surfaces, which should be free of oil and grease. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note