| –

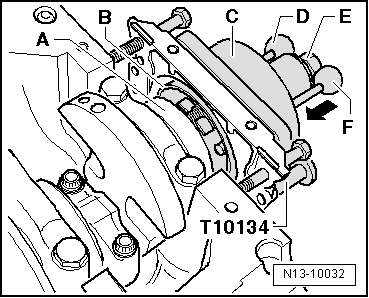

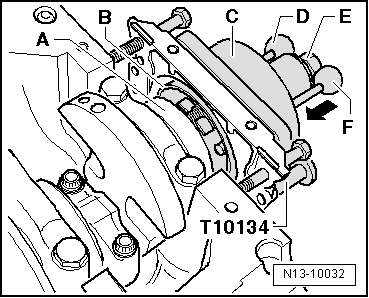

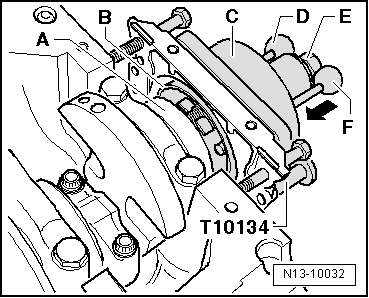

| Move the installation socket -C- by hand in the direction of the arrow until the sealing lip pressure ring -B- sits on the crankshaft flange -A-. |

| –

| Insert the guide pin for petrol engines (red handle) -F- into the crankshaft hole. In this way, the final fitting position of the sender wheel is established. |

Note | Do not insert the guide pin for diesel engines (black handle) -F- into the crankshaft hole. |

| –

| Tighten the Allen bolts of the assembly device by hand. |

| –

| Tighten the hexagonal bolt -E- on the threaded spindle until it comes into contact with the installation bell -C-. |

|

|

|

Note

Note

Note

Note