| –

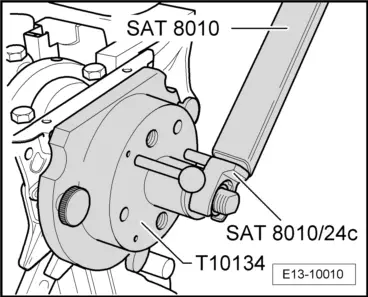

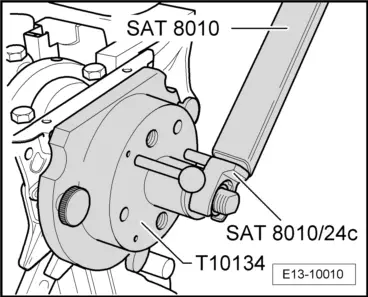

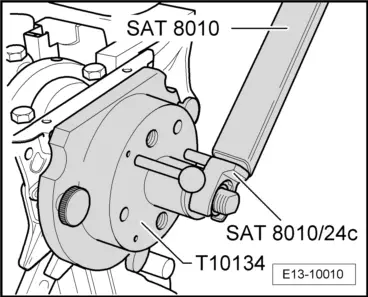

| Tighten the hexagonal nut of the assembly device -T10134- to a torque of 35 Nm with the torque wrench -SAT 8010- and the socket -SAT 8010/24C-. |

Note | After tightening the hexagonal bolt to 35 Nm, a small space should remain between the engine block and the sealing flange. |

|

|

|

Note

Note

Note

Note