| –

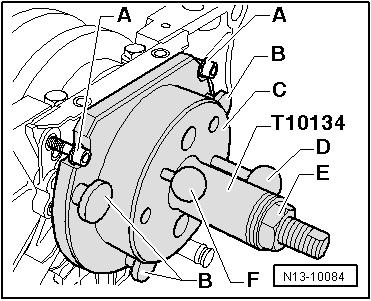

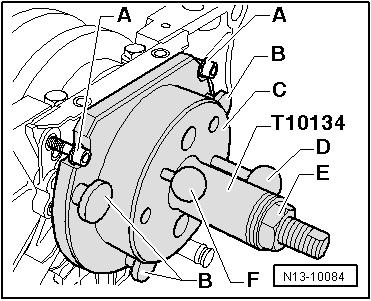

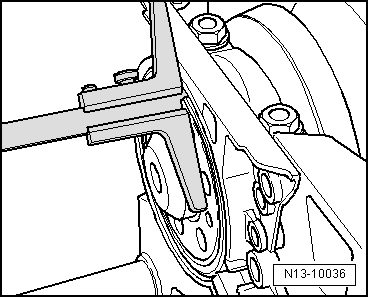

| Fit the dial calliper onto the crankshaft flange. |

| –

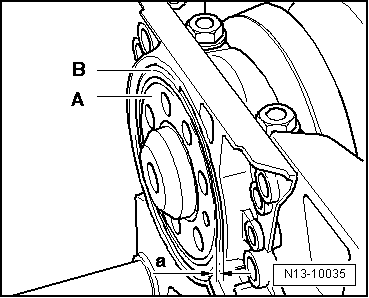

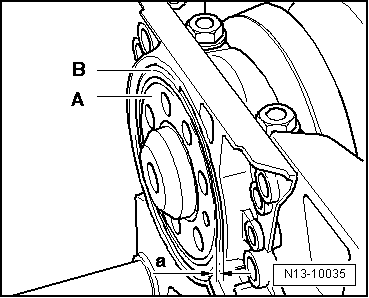

| Measure the distance -a- between the crankshaft flange and the sender wheel. |

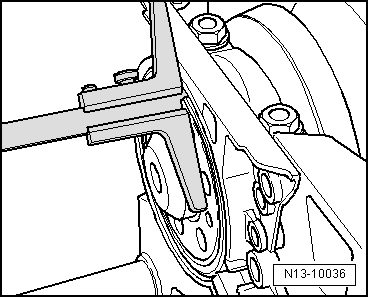

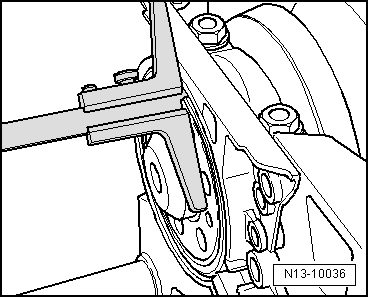

| If the dimension -a- is too small: |

| If the dimension -a- is reached: |

| –

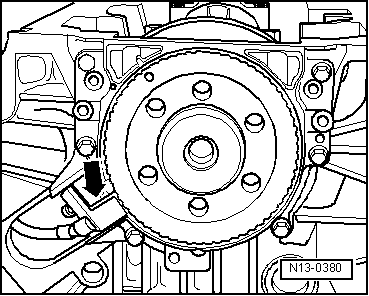

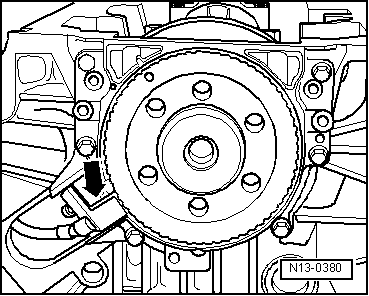

| Tighten the new bolts securing the sealing flange in diagonal pairs to 15 Nm. |

|

|

|