| –

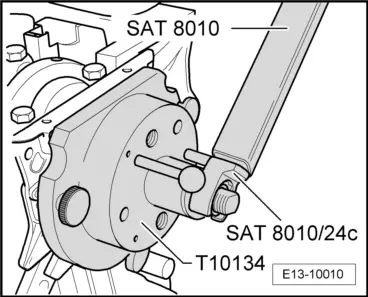

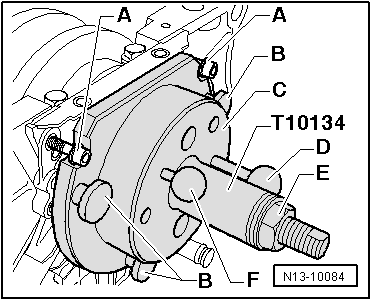

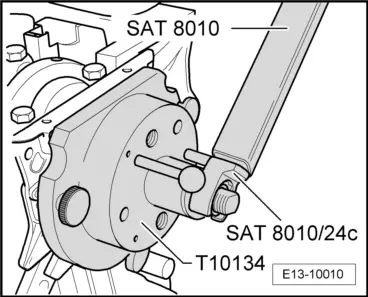

| Tighten the hexagonal nut of the assembly device -T10134- to a torque of 40 Nm with the torque wrench -SAT 8010- and the socket torque wrench fitting -SAT 8010/24C-. |

| –

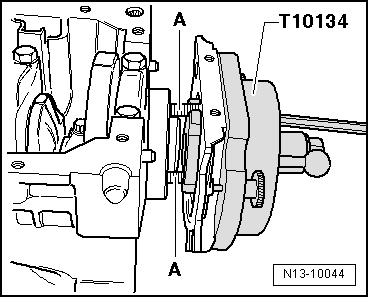

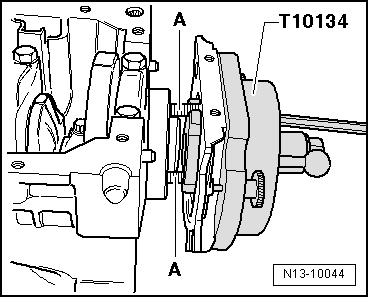

| Check the fitting position of the sender wheel on the crankshaft once more → Chapter |

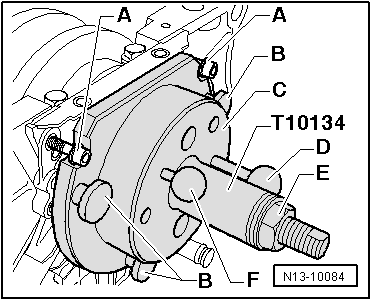

| If the dimension -a- is too small: |

| –

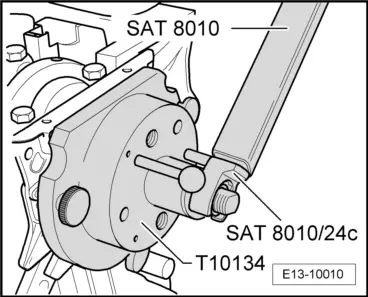

| Tighten the hexagonal bolt of the assembly device -T10134- to a torque of 45 Nm. |

| –

| Check the fitting position of the sender wheel on the crankshaft once more → Chapter |

|

|

|