| –

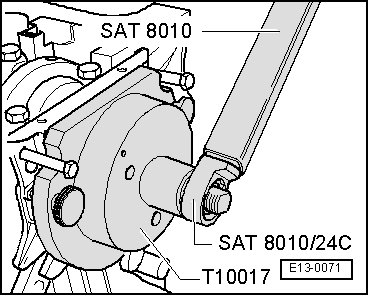

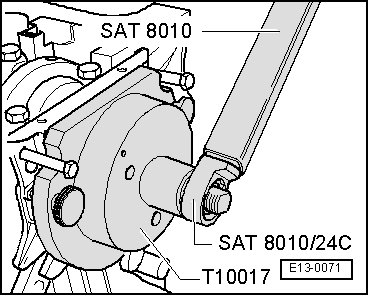

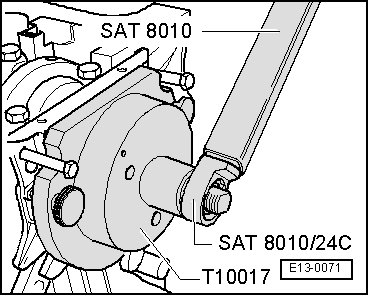

| Tighten the hexagonal nut of the assembly device with the torque wrench -SAT 8010- and the torque wrench -SAT 8010/24C-. Tightening torques: 35 Nm |

Note | A small air gap must be present between cylinder block and sealing flange after tightening hexagon nut to 35 Nm. |

|

|

|

Note

Note

Note

Note