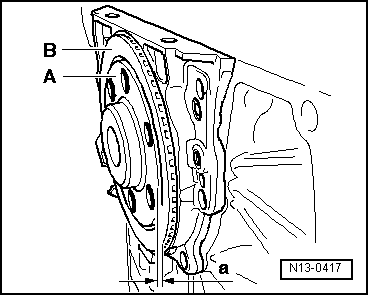

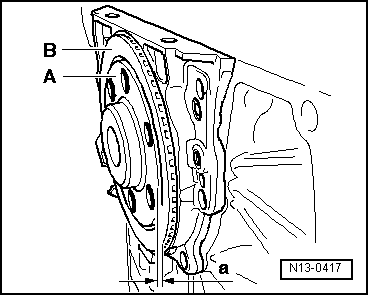

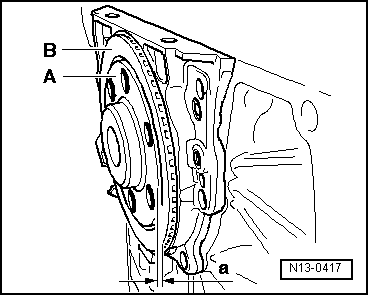

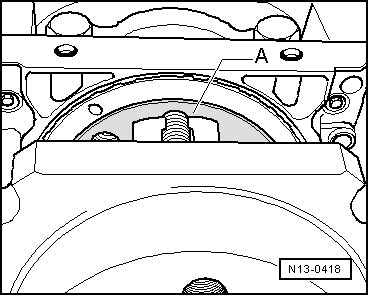

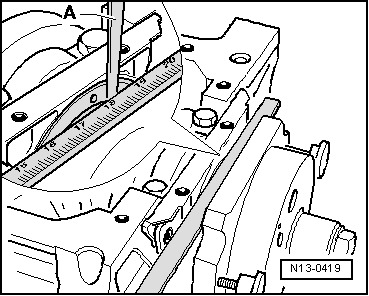

| The sender wheel is in the correct position on the crankshaft when the distance -a- between the crankshaft flange -A-and the sender wheel -B- is 0.5 mm. |

Note | t

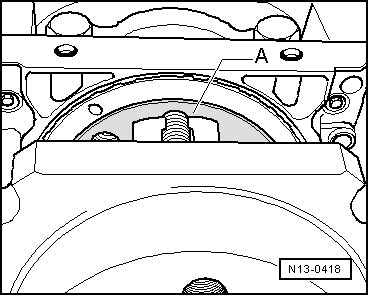

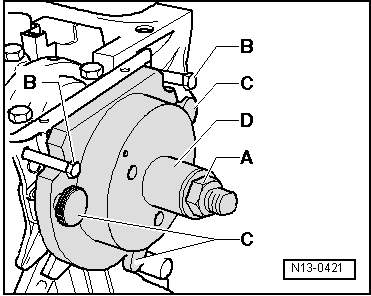

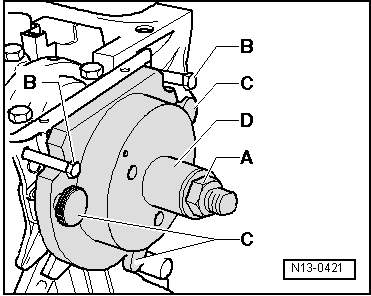

| On the sealing flange with PTFE seal, completely unscrew the centre guide -T10017- and remove the sealing lip pressure ring. |

| t

| To help identify distance -a-, the crankshaft flange is shown without the centre guide -T10017- bolted down. |

|

|

|

Note

Note

Note

Note