| –

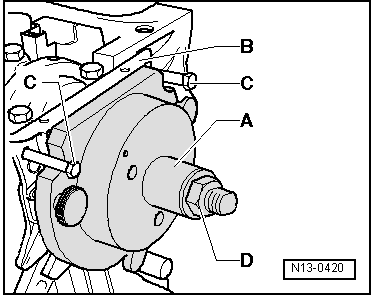

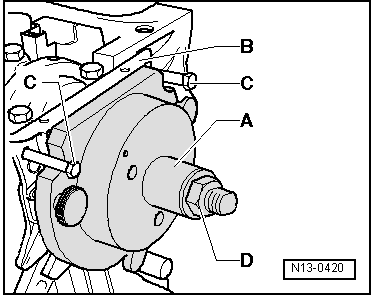

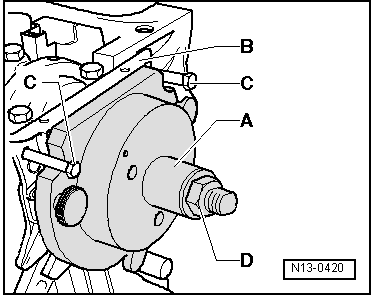

| Move the installation bell -A- by hand towards the sealing flange -B-. |

| –

| Screw in the 2 bolts M6 x 35 -C- on the engine block to guide the sealing flange -B-. |

| –

| Tighten by hand the hexagonal bolt -D- on the threaded spindle until it comes into contact with the installation bell -A-. |

|

|

|