| l

| Engine oil temperature at least. 30 ℃ |

| –

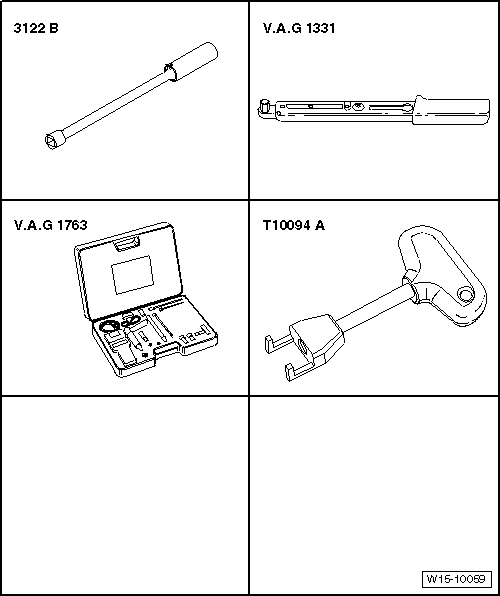

| Removing ignition coils. To do so, use the extractor -T10094 A-. |

| –

| Remove all glow plugs using wrench -3122 B-. |

| –

| Remove fuse number 6 from the fuse holder located below the instrument panel, on the left-hand side. |

Note | On removing fuse number 6, the voltage supply to the fuel pump control unit is interrupted. |

| –

| Check compression with compression tester -V.A.G 1763-. |

Note | See relevant test unit operating instructions for instructions on how to use test unit. |

| –

| Operate starter until tester shows no further pressure increase. |

| Max. deviation allowed between both cylinders: 3 bar |

| –

| Bolt on spark plugs with the spark plug wrench -3122 B- and tighten to 30 Nm. |

| Further assembly is basically the reverse of the dismantling sequence. |

| –

| Consult fault memory; if necessary, repair any faults and then erase fault memory diagnosis centre -VAS 505X-„guided fault finding“. |

| If the fault memory has been erased, you must generate the readiness code again. |

|

|

|

Note

Note Note

Note