| t

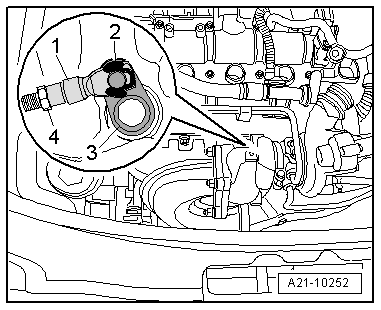

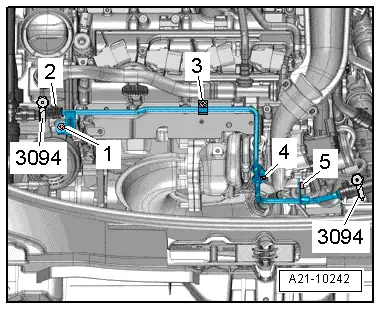

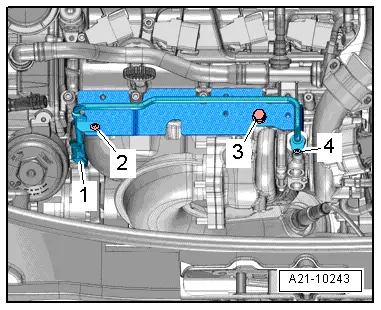

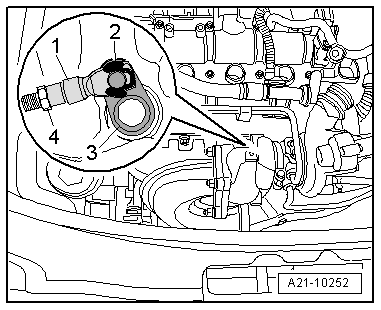

| If the theoretical value is not obtained, loosen the lock nut -4-. |

| t

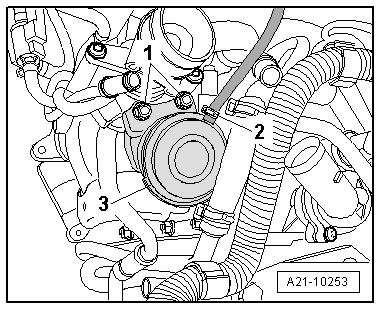

| Lever off safety washer -2-, then remove threaded part -1- on the control level rod -3-. |

| t

| Turn the threaded part on the control rod until the theoretical value is reached. To check, connect the threaded part to the control lever rod. |

| t

| Secure the threaded part with the safety washer -2- on the control lever rod and tighten the counter nut -4-. |

| Check the setting of the pressure capsule |

| –

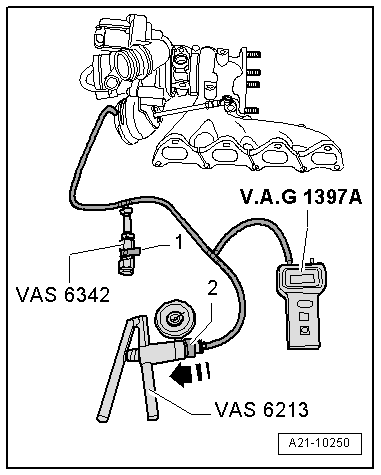

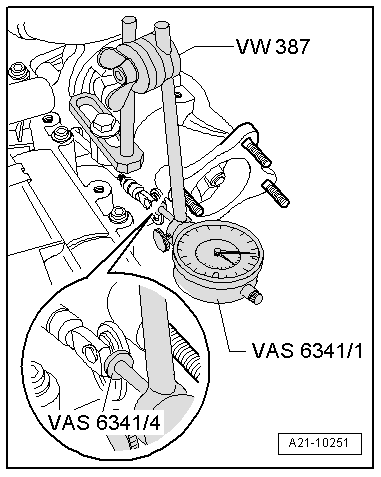

| At 0 bar, tense the gauge -VAS 6341/1- to 1 mm. |

| –

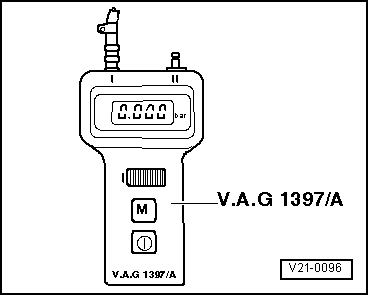

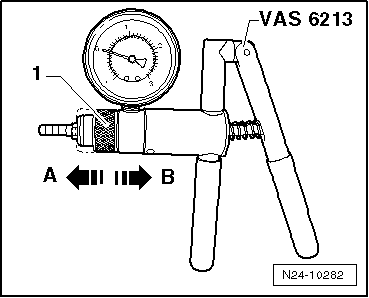

| Activate the manual vacuum pump -VAS 6213- several times until a pressure of 750 ... 800 mbar is shown on the turbocharger dial gauge -V.A.G 1397A-. |

| –

| Release pressure in the pressure control valve -VAS 6342- to 375 mbar. |

| –

| Read and note the value indicated by the gauge -VAS 6341/1-. |

| –

| Release pressure in the pressure control valve -VAS 6342- to 0 mbar. |

| –

| Activate the manual vacuum pump -VAS 6213- several times until a pressure of 375 mbar is shown on the turbocharger dial gauge -V.A.G 1397A-. |

| –

| Read and note the value indicated by the gauge -VAS 6341/1-. |

| –

| Calculate average value; by adding values „1“ and „2“ and dividing by 2. |

| –

| Activate the manual vacuum pump -VAS 6213- several times until a pressure of 750 ... 800 mbar is shown on the turbocharger dial gauge -V.A.G 1397A-. |

| –

| Release pressure in the pressure control valve -VAS 6342- to 475 mbar. |

| –

| Read and note the value indicated by the gauge -VAS 6341/1-. |

| –

| Release pressure in the pressure control valve -VAS 6342- to 0 mbar. |

| –

| Set the dial gauge -VAS 6341/1- indicator to "0". |

| –

| Activate the manual vacuum pump -VAS 6213- several times until a pressure of 475 mbar is shown on the turbocharger dial gauge -V.A.G 1397A-. |

| –

| Read and note the value indicated by the gauge -VAS 6341/1-. |

| –

| Calculate average value; by adding values „1“ and „2“ and dividing by 2. |

| –

| Repeat adjustment procedure if readings do not match specifications → Anchor. |

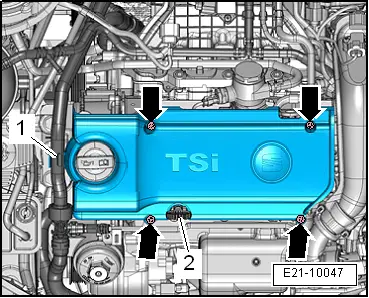

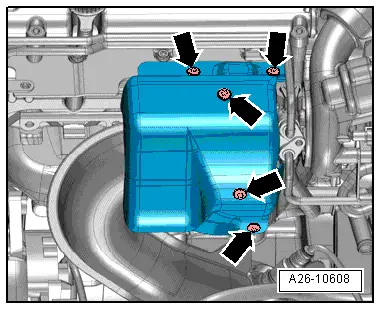

| Tightening torque of the heat protection plate for the exhaust gas turbocharger: 10 Nm |

| Install in the reverse order to removal. |

| –

| Mount the primary catalytic converter with exhaust pipe → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution