Leon Mk1

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

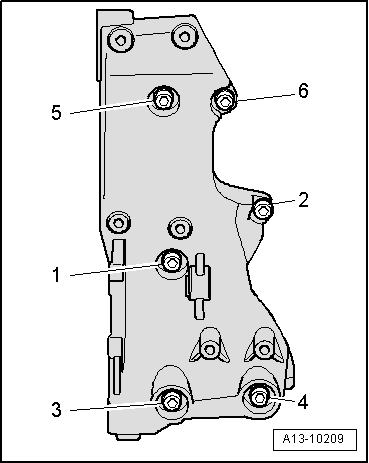

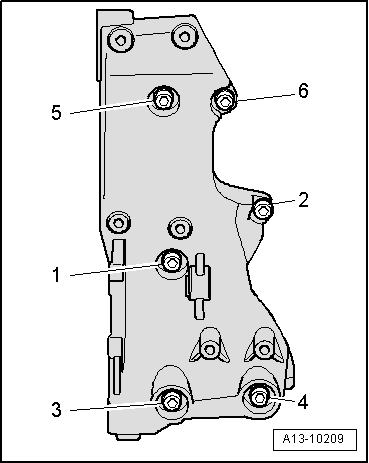

| Component | Nm | |

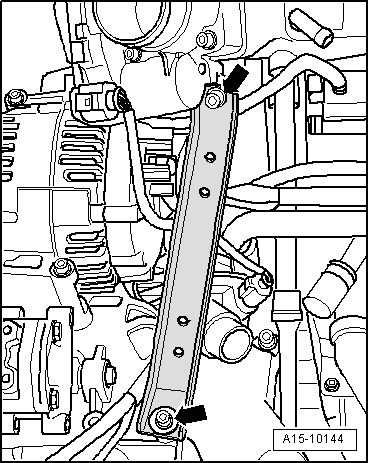

| Bracket for auxiliary units on engine block | 40 → Remark | |

| Support for | Bracket for ancillary mechanical units | 23 |

| Intake manifold to | Intake manifold | 23 |

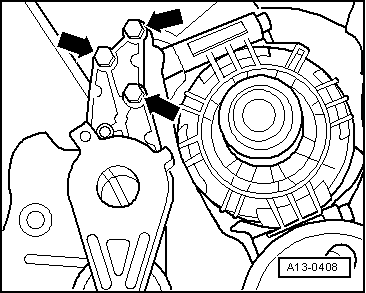

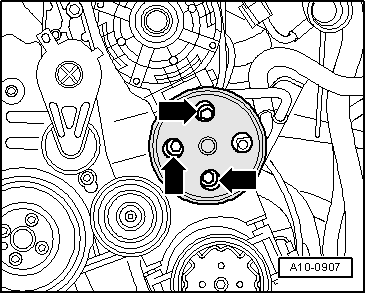

| Return roller to ancillaries bracket | 25 | |

| Ribbed belt tensioner to ancillaries bracket | 23 | |

|

Caution

Caution