Leon Mk1

|

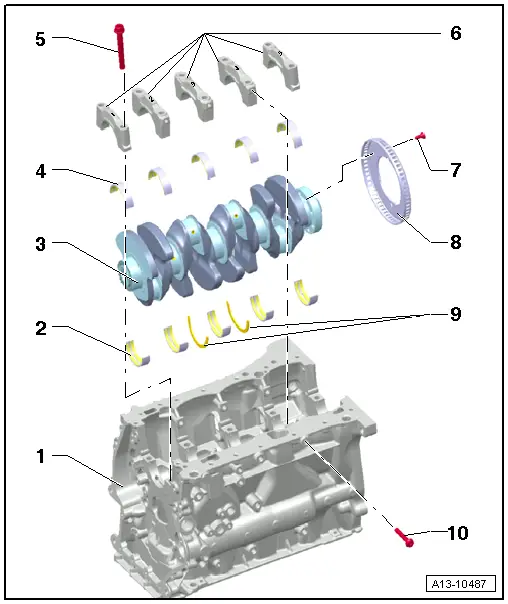

| 1 - | cylinder block |

| 2 - | Engine block bearing shell |

| q | With oil groove |

| q | Do not interchange used bearing shells (mark). |

| q | Identification of the crankshaft bearing shells → Chapter |

| 3 - | Crankshaft |

| q | Following removal, do not place on the impulse generator disk as this will be damaged. |

| q | Axial clearance → Chapter |

| q | Radial clearance → Chapter |

| q | Do not rotate crankshaft when checking radial clearance. |

| q | Crankshaft dimensions → Chapter. |

| 4 - | Bearing cap |

| q | Without oil groove |

| q | Do not interchange used bearing shells (mark). |

| q | The half bearing shells for the bed plate bearing caps are supplied as replacement part only with the colour coding „yellow“ |

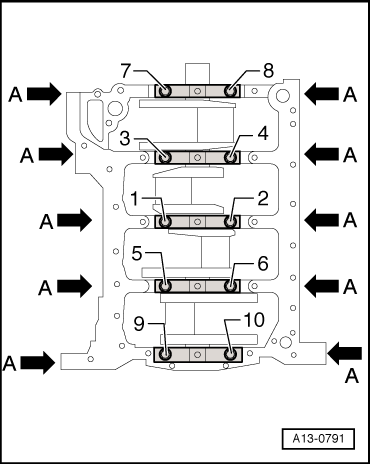

| 5 - | Bolt. |

| q | Replace |

| q | Tightening sequence → Fig. |

| 6 - | Bearing cap |

| q | Bearing cap 1: Pulley side: |

| q | Bearing shell retaining lugs in cylinder block and bearing caps must align. |

| 7 - | Bolt. |

| q | 10 Nm + further 1/4 (90°) |

| q | Replace |

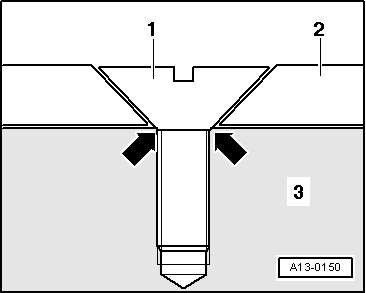

| q | Always renew sender wheel if bolts have been loosened - → Fig. |

| 8 - | Generator wheel: |

| q | For engine speed sender -G28- |

| q | Can only be installed in one position. Holes are off-set |

| q | Always renew sender wheel if bolts have been loosened |

| q | Removing and installing → Fig.. |

| 9 - | Thrust washers |

| q | For bearing 3. |

| 10 - | Bolt. |

| q | 20 Nm + further 1/4 (90°) |

| q | Replace |

Note

Note

|

|