| –

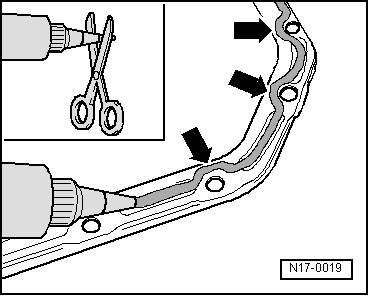

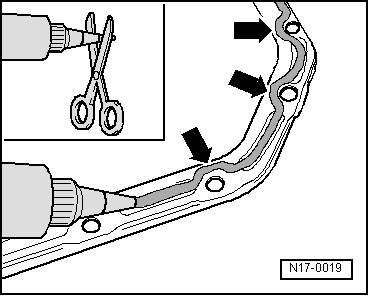

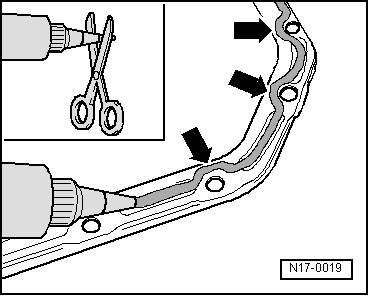

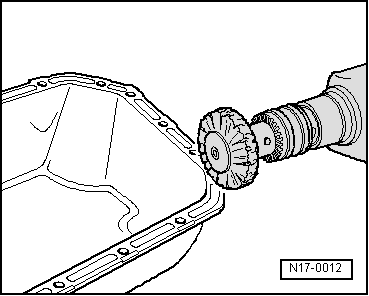

| Cut off tube nozzle at upper marking (nozzle Ø: approx. 3 mm). |

| –

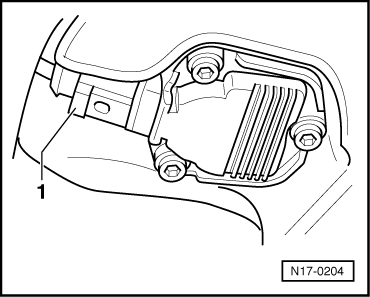

| Apply silicone sealing compound, as shown, to clean sealing surface on sump. The strip of sealant must: |

| t

| Run bead along inner side of bolt holes -arrows-. |

Note | The sealant bead must not be thicker. Otherwise the excess sealant may enter the oil sump, and obstruct the strainer in the oil intake pipe. |

| –

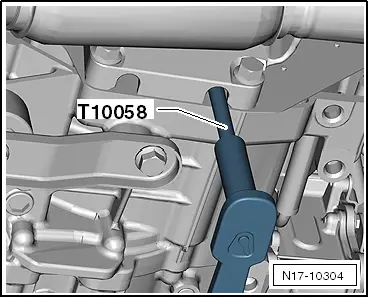

| Install sump immediately and tighten all sump bolts lightly. |

| –

| Tighten oil sump bolts to 13 Nm. |

Note | Starting can be carried out 30 minutes after applying the sealant to the oil sump. Only then should the engine be refilled with oil. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note