| –

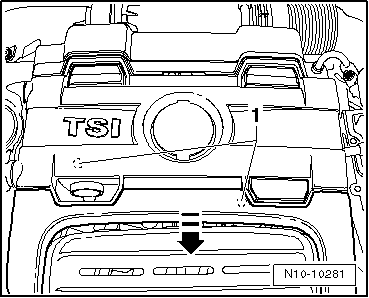

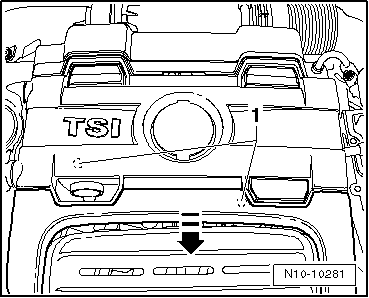

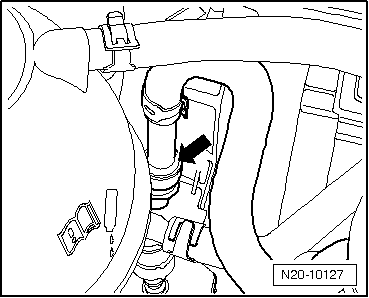

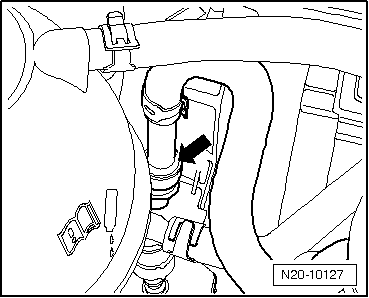

| Lift off engine cover panel at points -1- and pull it forwards in direction of -arrow-. |

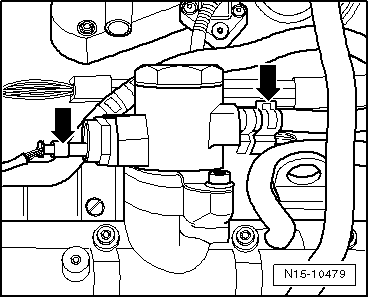

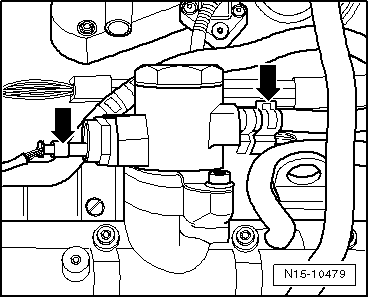

WARNING | The injection system is sub-divided into a high pressure system (max. approx. 120 bar) and a low pressure system (approx. 6 bar). |

| Prior to opening the high-pressure area, e.g. when removing the high-pressure pump, fuel rail, injectors, a fuel line, or the fuel pressure sender -G247-, the fuel pressure in the high-pressure area must be reduced to a residual pressure of approx. 6 bar. The appropriate procedure is described in the chapter on releasing pressure in the high-pressure section → Chapter. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution