| –

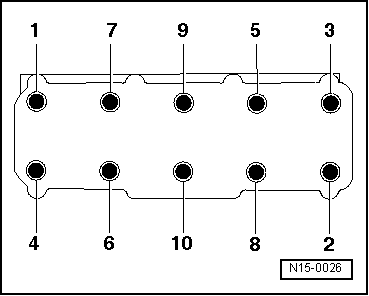

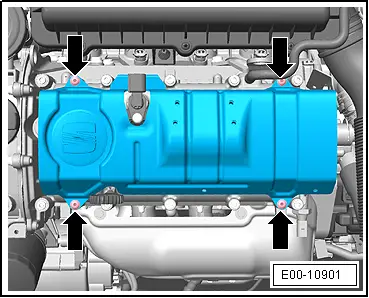

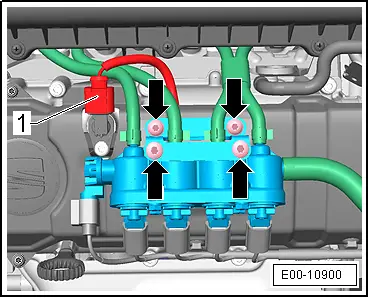

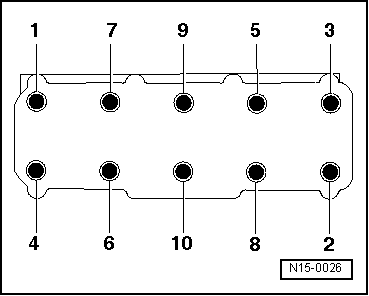

| Loosen socket head bolts in the sequence given and then remove completely. |

| –

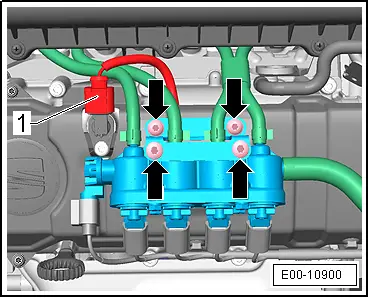

| Carefully remove cylinder head. |

| l

| Pistons must not be at TDC. |

Note | t

| Do not remove the new cylinder head gasket from its packing until immediately before its installation. |

| t

| Handle new gasket with extreme care. If damaged, leaks may result. |

| –

| Place clean cloths in cylinders so that no dirt or emery cloth particles can get in between cylinder wall and piston. |

| –

| Carefully clean the sealing surfaces on the cylinder head and cylinder block. Ensure no long grooves or scratches are produced (if using sandpaper. it must be at least 100 grain). |

| –

| Carefully remove metal particles, emery residue and cloths. |

| –

| Set No. 1 cylinder piston to top dead centre and then turn crankshaft back slightly. |

| –

| Fit new cylinder head gasket. Lettering (Part No.) must be readable. |

| –

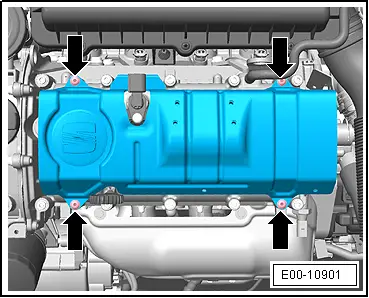

| Fit cylinder head. When doing this, observe centring pins in cylinder block. |

| –

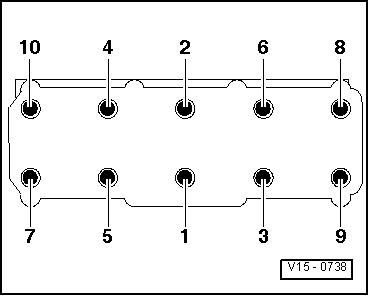

| Insert cylinder head bolts and tighten by hand. |

|

|

|

Note

Note

Note

Note