| Special tools and workshop equipment required |

| t

| Fault reader -V.A.G 1551- or vehicle system checker -V.A.G 1552- with cable -V.A.G 1551/3B- |

| t

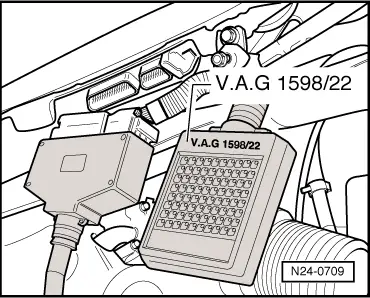

| Checking box -V.A.G 1598/22- |

| t

| Manual multimeter -V.A.G 1526 A- or multimeter -V.A.G 1715- |

| t

| Auxiliary measuring set -V.A.G 1594 C- |

| t

| Current circuit diagrams |

| l

| Battery voltage, 11.5 V minimum. |

| l

| All electrical consumers, for example: the lights and heated windscreen, must be turned off. |

Note! | To check the speed signal, the vehicle must be driven. To do this, the help of a second person is required. |

Caution | The fault reader must be fixed on the back seat and handled from there. |

|

| –

| Connect the -V.A.G 1551- (-V.A.G 1552-), and using the corresponding “direction code” 01, select the control unit for engine electronics. When doing this, the engine must be idling: (Fault reader: Turn on and select the control unit for engine electronics → Chapter). |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!