| These engines are fitted with two-spring injectors; therefore, the fuel is injected in two phases. |

| If these injectors fail, they must be replaced as it is not possible to adjust the pressure or repair them. |

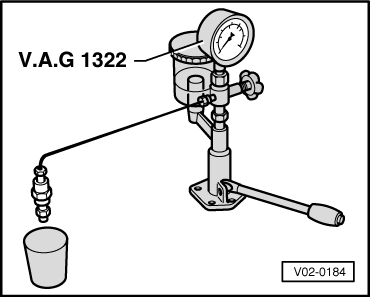

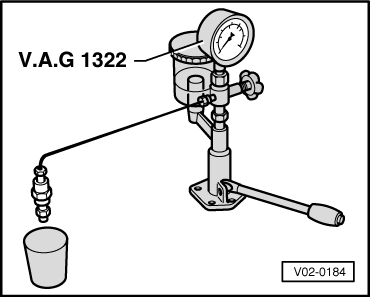

| Special tools and workshop equipment required |

| t

| Injector checker -V.A.G 1322- with Pressure pipe -V.A.G 1322/2- |

| Check the pressure of the spray projection |

Caution | When checking the injectors, make sure that the fuel spray does not reach your hands as the high pressure makes the fuel enter the skin, which may cause serious harm. |

|

|

|

|