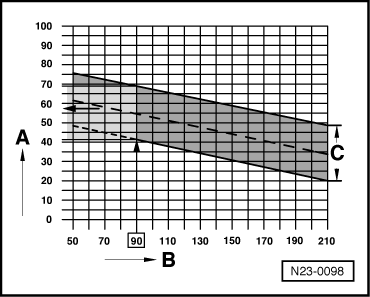

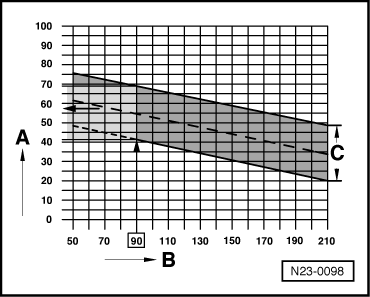

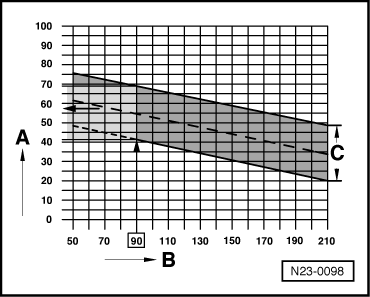

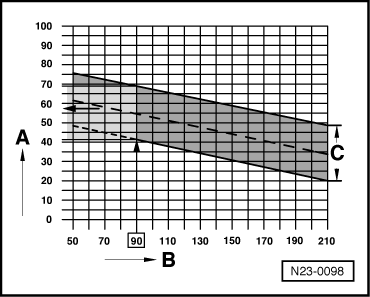

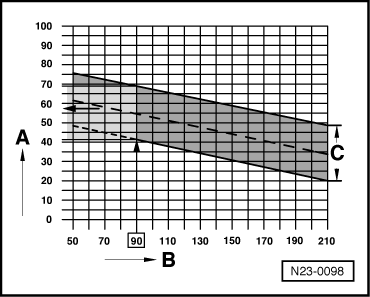

| Start of injection, display zone 2, depends on the fuel temperature, display zone 9. |

| A - | Display zone 2, injection start |

| B - | Display zone 9, fuel temperature |

| C - | The tolerance range for the injection start |

| The numeric value 90 in the display zone 9 -B-, corresponds in display zone 2 -A- to a range of 42...69. |

Note! | t

| In the case of untimely injection start, the injection pump must be turned in the direction of engine rotation, if the start of injection is late, turn the pump in the opposite direction. |

| t

| If when checking the injection start is within the range indicated -C-, a new adjustment is not necessary. |

| t

| After repairs, such as the removal or installation of the injector pump or the adjustment of the distribution times, the injection start should be adjusted to the average value (traced line) of the tolerance range -C-. |

| –

| Withdraw approximately one turn the securing bolts of the injection pump, finishing with the most accesible bolt. |

| –

| Hold the injection pump with your hand, with a certain amount of pre-tension in the direction of the adjustment. |

| –

| Carefully loosen the last securing bolt to the point where the pump can turn a little, then tighten the bolt again. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!