Leon Mk1

| Gearbox: removing and installing |

| Consult the tool and equipment equivalence tables for Seat / VW / Audi / Skoda → Chapter. |

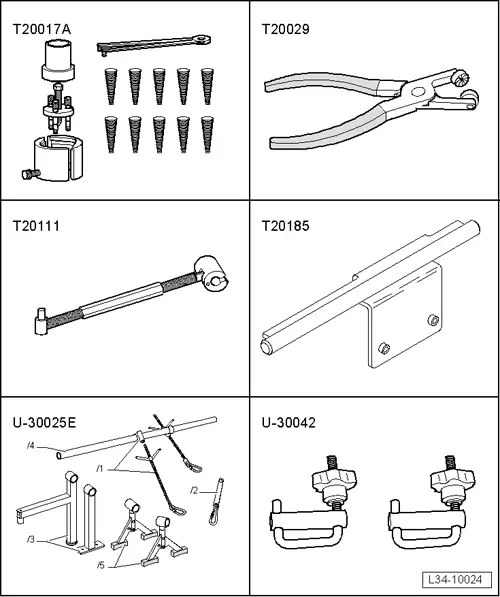

| Special tools and workshop equipment required |

| t | Kit (box) -T20017A-, see equivalent → Anchor |

| t | Pliers -T20029-, see equivalent → Anchor |

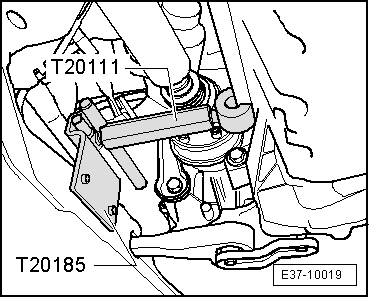

| t | Holding tool -T20111-, see equivalent → Anchor |

| t | Holding tool -T20185-, see equivalent → Anchor |

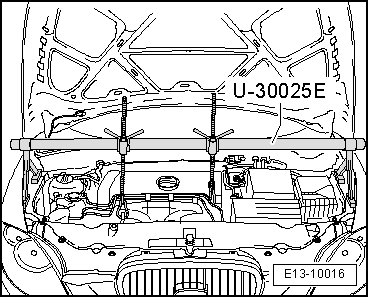

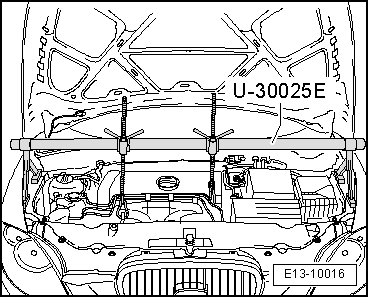

| t | Support -U-30025E-, see equivalent → Anchor |

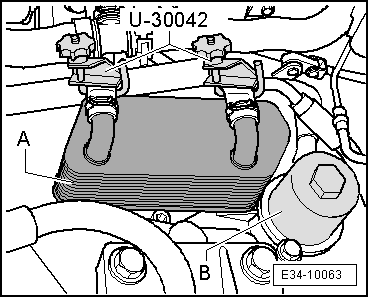

| t | Pressure tool -U-30042-, see equivalent → Anchor |

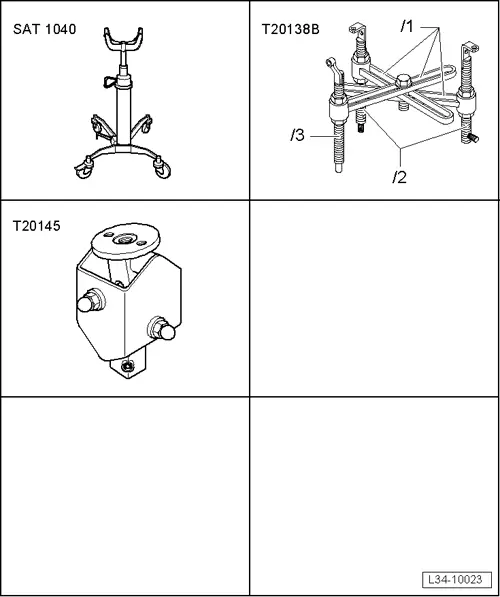

| t | Hydraulic jack -SAT 1040-, see equivalent → Anchor |

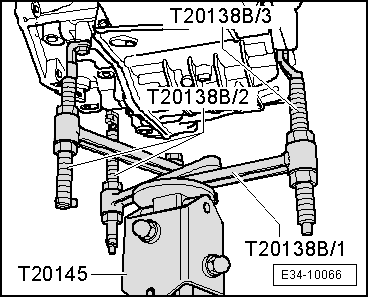

| t | Holding tool -T20138B-, see equivalent → Anchor |

| t | Base -T20145-, see equivalent → Anchor |

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

WARNING

WARNING