Leon Mk1

Note

Note

|

|

|

|

|

|

|

|

|

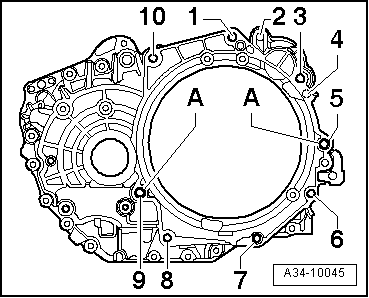

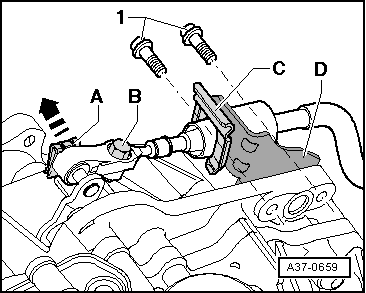

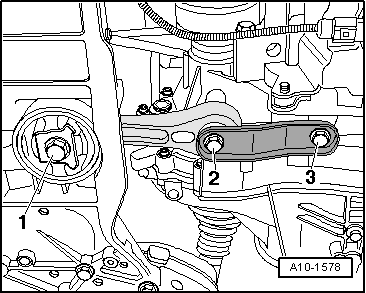

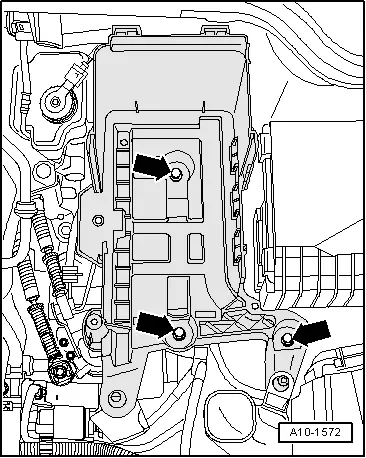

| Screws -1- | 50 Nm + 90° (1/4 turn) |

|

|

|

|

|

|

|

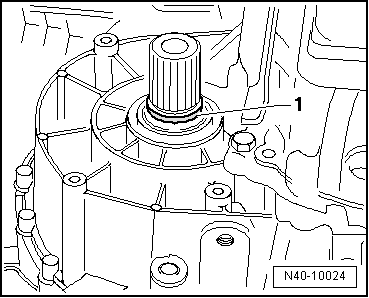

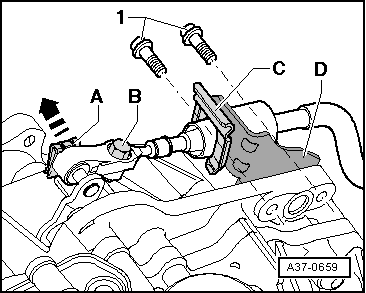

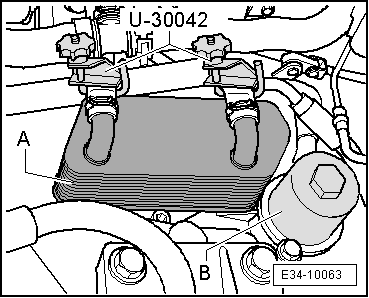

| 2 bolts -1-, M8 | 20 Nm + 90° (1/4 turn) |

|

|

|

|

|

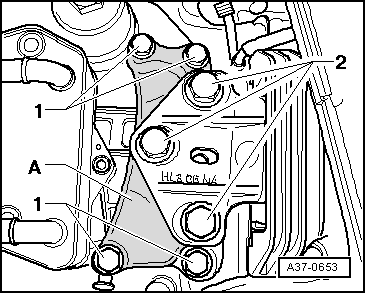

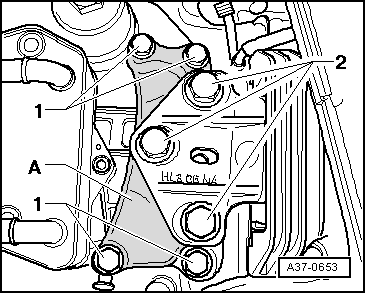

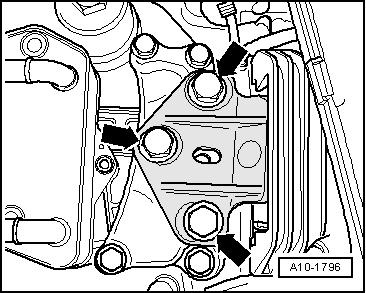

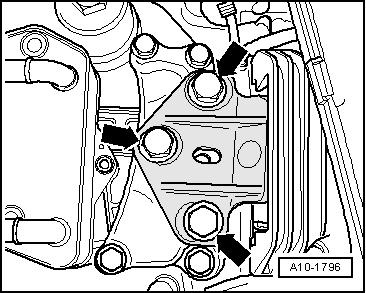

| Bolts -arrows- | 100 Nm |

Note

Note

|

|

|

|

|

|

|

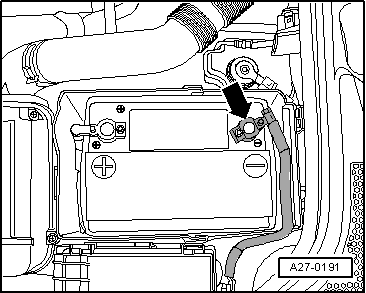

WARNING

WARNING